The right forklift battery charger will keep your battery healthy and optimize your forklift’s performance for as long as possible.

Let’s go through some important tips and formulas that will help you select the right battery and charger for your lift truck and then calculate the proper charge output for the matching battery charger. Click on each section to learn more.

1. Are All Forklift Batteries the Same?

2. How Do I Know What Size of Battery Charger I Need?

3. Should Your Battery and Charger Be the Same Brand?

4. Should You Get a Forklift Battery Charger that Monitors Battery Temperature?

5. What Forklift Charger Brands Are the Least Expensive?

6. Which Forklift Charger Brands Are the Most Reliable?

7. What Should I Pay for a Forklift Battery Charger?

8. Is There a Difference Between a Lithium Forklift Battery Charger and a Lead-Acid Forklift Battery Charger?

9. How to Charge a Lithium-Ion Forklift Battery

10. How to Charge a Lead-Acid Forklift Battery

11. Three Types of Forklift Battery Charging

12. Forklift Charging Station Power Requirements

13. High Efficiency Forklift Battery Charger vs Electric Forklift Battery Charger

14. Benefits of a Lithium-Ion Forklift over a Lead-Acid Forklift

As popularity and demand increases for Electric Powered Forklifts, choosing the right lift truck battery charger is more important than ever. The wrong charger can damage your battery and void your warranty. And with batteries costing $4,000 to $20,000 each, no one wants to shorten the life of this expensive investment.

The experts at Ri-Go can help you make the right choice. Contact us today, and we will step you through the process.

Forklift Battery Charger: Your Ultimate Guide

1. Are All Forklift Batteries the Same?

Discover everything you need in order to purchase an electric forklift charger.

No, forklift batteries are not all the same. Before you select your forklift battery charger, you need to make sure you have the correct battery.

The following are some key factors to look at when choosing a forklift battery:

Weight:

For a lift truck, the battery is a large part of the counterweight of the truck, so it’s crucial that it has the correct weight or the truck will not lift its rated load nor will it pass safety inspections. The battery MUST be the correct size and weight to ensure the forklift can lift what it is rated to lift.

You should read the truck’s capacity plate to find the MIN and MAX weight for the battery. This is very important. A battery that is too heavy will strain the truck’s steer axle and components unnecessarily and could void parts of the manufacturer’s warranty.

Voltage:

The battery must of course be the correct voltage for the truck. To determine what voltage your battery and charger must be, it is best to check the forklift’s spec plate. The voltage should be clearly marked on the spec plate under the model and serial number of the unit.

In Canada, these voltages are usually 24V, 36V, 48V and 80V. The higher the voltage generally the more efficient the battery will deliver power resulting in longer run times between charges.

Size:

Next measure the battery compartment and ensure you get a battery that fits the truck well. The battery should be big enough to fit without too much extra space which would result in the battery moving around while turning or braking the truck. A battery that is too small will also mean the truck cannot lift its rated load nor will it pass a safety inspection.

Ah Capacity:

“Ah” stands for Amp-hours. This is a unit of measurement that measures how much current a battery will give you at a specific rate for a certain period of time. In other words, it measures your battery’s energy capacity. Once you get the right voltage and forklift battery Size, (not too big nor too small) and you ensure it meets the minimum weight specified on the truck spec plate, then you can choose the Ah Capacity that fits that requirement.

For example, if you have a fully-charged 220-Ah battery, it can give you 220 amps of current for one hour. The more Ah (amp hours) the bigger the “fuel tank” and the longer the truck will run, but the more that battery will cost too.

Now you have picked the proper forklift battery type for the lift truck and can select the correct charger.

2. How Do I Know What Size of Battery Charger I Need?

A higher voltage charger will be more efficient – Image source: Linde

When selecting a lift truck battery charger, you need to consider both your building Input Voltage and Phasing and the Output Voltage and AH.

Building Input Voltage and Phasing:

The input is determined by your building’s power. You may need to ask your electrician to help you with this or you can read your building electrical box to find out what your input voltages are. Normal input voltages in Canada for forklift chargers include the following:

- 208/240V single

- 3 phase

- 600 Volt 3 Phase

The higher the voltage, the more efficient the charger will be and the lower the cost per charge for your operation Therefore, if you have the choice, you should select the 600V 3 phase.

Output Voltage and AH:

If you have a 48 Volt forklift and 48 Volt battery you need a 48 Volt forklift battery charger. To determine the size of Ah output you will need, here is a general rule to follow:

- For Standard Charge: 17% of the Battery AH

- For Opportunity Charge: 25% of the Battery AH

- For Fast Charge: 40% of the Battery AH

So for example, if you have a 510Ah battery you would need the following outputs:

- Standard Charge: 87 Amp Output

- Opportunity Charge: 128 Amp Output

- Fast Charge: 204 Amp Output

If you are still unsure, you can ask an electric forklift charger supplier you trust to help you select the right charger.

3. Should Your Battery and Charger Be the Same Brand?

It’s best to buy the same brand of lift charger and battery if possible. – Image source: Linde

Normally the best option for your charger is to try to purchase the same brand charger as your battery if possible. Each brand usually has its own particular type of connectors and charging requirements.

You should use a charger that is compatible with your forklift and battery manufacturer. This helps protect your warranty and ensures simpler and more effective technical support should you need it down the road.

4. Should You Get a Forklift Battery Charger that Monitors Battery Temperature?

Ask a professional about forklift battery and charger specifications. – Image Source: Komatsu

When buying a forklift battery charger it is a good idea to choose one that can monitor your battery temperature and can adjust the charge rate when the temperature falls out of the normal range. This feature is great as it helps regulate the temperature and can prevent overheating the battery. This will have a positive impact on the life of the battery and its run times.

When selecting a forklift battery charger, ask your lift truck professional at Ri-Go Lift for the best forklift batteries and charger options. Discuss new technologies and features in your battery and charger purchases. We have new and used options that could meet your individual requirements best.

5. What Forlift Charger Brands Are the Least Expensive?

Hangcha offers inexpensive, quality lithium battery forklifts.

While cost is certainly a crucial factor when choosing a forklift battery charger, focusing solely on the “least expensive” brands might not be the wisest approach. Here’s why:

Hidden Costs of “Bargain” Chargers:

Make sure you consider some of the following hidden costs when it comes to getting lower prices forklift batteries and chargers:

- Lower quality components: This can lead to frequent breakdowns, higher repair costs, and shorter lifespan.

- Limited features: May lack essential features like safety cut-offs, temperature monitoring, or data logging, compromising safety and efficiency.

- Poor customer support: Difficult to obtain replacement parts or troubleshoot issues, leading to downtime and lost productivity.

Smart Considerations Beyond Price:

Here are some important factors to consider when purchasing your forklift battery charger other than simply the cost.

- Total Cost of Ownership (TCO): Consider not just the initial purchase price, but also long-term costs like repairs, maintenance, energy consumption, and warranty support.

- Reputable Brands: Opt for established brands with proven track records for quality, reliability, and customer service.

- Charger specs & Compatibility: Ensure the charger matches your specific forklift type, battery voltage, and power requirements.

- Dealer Network & Support: Choose a brand with readily available local service and parts to minimize downtime in case of issues.

Instead of focusing solely on the “least expensive,” you should prioritize the following:

- Value for Money: Look for brands that offer a good balance of affordability, quality, and features.

- Reliable Performance: Choose a brand known for durable and dependable chargers.

- Trusted Support: Select a brand with readily available and responsive customer service.

Remember: The cheapest option upfront might end up costing you more in the long run.

6. Which Forklift Charger Brands Are the Most Reliable?

Learn about the great features and benefits of the reliable Komatsu BH18A battery hauler charger.

Ultimately, the “most reliable” forklift charger brand will depend on your specific needs and budget.

By prioritizing the following factors and consulting with reputable material handling specialists, you can identify well-established brands offering chargers that deliver optimal performance, longevity, and support for your specific application.

Industry Reputation:

Look for brands with a longstanding presence in the material handling industry and a reputation for quality and innovation, such as Linde or Komatsu. You can research online reviews, industry publications, and customer testimonials to gauge user experiences and brand feedback.

Product Quality and Features:

Consider brands known for using high-quality components and materials in their chargers, leading to longer lifespans and fewer breakdowns. Assess the range of features offered, ensuring they align with your specific needs and optimize battery performance and safety.

Customer Service and Support:

Choose brands with readily available and responsive customer support teams who can provide timely assistance if needed. Evaluate the accessibility of local service technicians and spare parts to minimize downtime in case of issues.

Warranty and Guarantees:

For greater peace of mind, choose brands that offer comprehensive warranties covering the following:

- Parts

- Labour

- Potential Repairs

Consider extended warranty options if they provide significant value based on your usage and risk tolerance.

Industry Certifications and Compliance:

Select brands whose chargers adhere to relevant industry standards and safety regulations, ensuring reliable performance and operator safety.

7. What Should I Pay for a Forklift Battery Charger?

Consider your total cost of ownership, not just the initial price when selecting forklift batteries & chargers.

As with any equipment purchase, determining the “right” price for a lift truck battery charger depends on various factors, and focusing solely on a specific dollar amount can be misleading. Here’s what to consider instead:

Factors Influencing Charger Price

The following factors will affect how much forklift chargers cost:

- Forklift Type and Battery: Different forklift models and battery sizes require chargers with varying capacities and functionalities, impacting cost.

- Technology and Features: Advanced features like temperature compensation, multi-stage charging, and data logging increase cost but enhance efficiency and lifespan.

- Brand Reputation and Warranty: Established brands with proven quality and comprehensive warranties often justify a higher price tag.

- Dealer Support and Service: Reliable local support for parts and service can save time and money in the long run, potentially justifying a slightly higher initial cost.

Instead of Asking “How Much,” Ask:

Here are some great questions to ask to help you choose the best electric forklift charger:

- What features do I need for my specific forklift and operation? Prioritize essential features for optimal performance and battery life.

- What is the charger’s expected lifespan and warranty coverage? A durable charger with a good warranty can save money in the long run.

- What is the total cost of ownership (TCO), including maintenance, repairs, and energy consumption? Consider long-term costs, not just the upfront price.

- Can I afford downtime due to unreliable support or parts availability? Reliable local support can be worth paying for to minimize downtime costs.

Remember: The cheapest option often comes with hidden costs. It might lack features, have a shorter lifespan, or require more frequent repairs, ultimately costing you more. Investing in a quality charger from a reputable brand can save you money in the long run.

Consult with a qualified professional. They can assess your specific needs and recommend the best charger for your budget and operation. By focusing on value, features, and long-term costs, you can make an informed decision about the right forklift battery charger for your business, ensuring optimal performance and cost-effectiveness.

8. Is There a Difference Between a Lithium Forklift Battery Charger and a Lead-Acid Forklift Battery Charger?

Discover how a lead acid battery works by watching the above video.

Yes, there are significant differences between lithium and lead-acid forklift battery chargers because there are significant differences between the two types of batteries. Here are some of the most significant differences:

Charging Technology

Lithium-Ion: Lithium chargers use sophisticated multi-stage charging protocols with precise voltage and current regulation for optimal battery health and safety.

Lead-Acid: Typically, lead-acid chargers use simpler charging mechanisms, often lacking the complex algorithms and safety features found in Lithium chargers.

Charging Speed

Lithium-Ion: Lithium-ion charges significantly faster due to different chemical properties and less risk of overcharging.

Lead-Acid: Lead-acid batteries take longer to charge (often overnight) and require regular monitoring to avoid damage from overcharging.

Features and Functionality

Discover how a lithium-ion battery works by watching the above video.

Lithium-Ion: Lithium-ion chargers are often equipped with advanced features like temperature monitoring, data logging, and communication protocols for improved battery management and diagnostics.

Lead-Acid: Lead-acid chargers typically have fewer features and functionalities compared to Lithium chargers.

Cost

Lithium-Ion: Lithium forklift battery chargers are generally more expensive than Lead-Acid chargers due to their advanced technology and components.

Lead-Acid: Lead-acid chargers are typically less expensive, but the lower upfront cost needs to be weighed against potential long-term costs associated with shorter lifespan and more frequent charging cycles.

Compatibility

Lithium-Ion: Lithium-ion chargers are specifically designed for lithium batteries and shouldn’t be used with lead-acid batteries due to different charging requirements.

Lead-Acid: Lead-acid chargers are more universal and can sometimes be used with different lead-acid battery types, but always confirm compatibility before use.

Overall

Lithium-ion chargers offer faster charging, better efficiency, and advanced features, while Lead-Acid chargers are typically more affordable. The best choice for you depends on your specific needs, budget, and forklift type.

9. How to Charge a Lead-Acid Forklift Battery

Lead-acid batteries need watering and equalization charging.

Charging a lead-acid forklift battery correctly is crucial for its lifespan, performance, and safety. Here’s a simple guide:

Preparation

Consult the battery and charger manuals: Each model has specific requirements for safe and effective charging.

Ensure proper ventilation: Batteries emit hydrogen gas during charging, so adequate ventilation is crucial.

Clear the charging area: Remove flammable materials and ensure proper access for connecting and disconnecting the charger.

Wear personal protective equipment (PPE): Safety glasses and gloves are recommended during the charging process.

Charging Process

Connect the charger: Verify the polarity matches the battery terminals (positive to positive, negative to negative).

Set the correct charging parameters: Follow the recommended voltage and current settings based on the battery capacity and charger specs.

Monitor the charging process: Regularly check the battery temperature, electrolyte level, and charging indicator lights.

Disconnect the charger once fully charged: Never overcharge the battery, as it can damage the plates and shorten its lifespan.

Additional Tips

- Use a timer to automatically shut off the charger when full.

- Avoid topping-up charges unless necessary, as they can accelerate degradation.

- Equalize the charge periodically (consult the manual) to balance cell voltages.

- Maintain proper electrolyte level with distilled water to avoid exposing the plates.

- Clean the battery terminals regularly to prevent corrosion.

- Store batteries in a cool, dry place when not in use.

Remember: Safety is paramount. If unsure, consult a qualified technician or follow the manufacturer’s instructions meticulously. By following these steps and adhering to safety precautions, you can ensure your lead-acid forklift battery receives proper charging, maximizing its performance and lifespan.

10. How to Charge a Lithium-Ion Forklift Battery

Watch the above video to get a better idea of the lithium forklift battery charging process.

Charging lithium-ion batteries differs from lead-acid counterparts, requiring specific procedures for optimal performance and longevity. Here’s a guide:

Preparation

Consult the battery and charger manuals: Thoroughly read and understand specific instructions for your battery and charger model.

Ensure proper ventilation: Adequate ventilation is vital, even though lithium batteries don’t emit harmful gas during charging.

Clear the charging area: Remove flammable materials and allow easy access for connecting and disconnecting the charger.

Wear personal protective equipment (PPE): While generally safer than lead acid, safety glasses and gloves are still recommended.

Charging Process

Connect the charger: Verify polarity matches the battery terminals (positive to positive, negative to negative).

Leave charging settings on automatic: Unlike lead-acid, most lithium chargers handle charging profiles automatically.

Monitor the charging process: Periodically check the battery temperature and charging indicator lights.

Disconnect the charger when full: Most chargers automatically shut off, but verify and disconnect if needed.

Additional Tips

- Lithium batteries generally allow “opportunity charging” – short, frequent charges during breaks – for added flexibility.

- Avoid high ambient temperatures during charging, as it can degrade battery performance.

- Store batteries in a cool, dry place when not in use, ideally around 50% charge.

- Consult the manufacturer for specific recommendations on long-term storage charging procedures.

Remember: While less maintenance-intensive than lead-acid, follow best practices for optimal performance and lifespan. By following these guidelines and adhering to safety precautions, you can ensure your lithium-ion forklift battery receives proper charging, maximizing its efficiency and durability.

11. Three Types of Forklift Battery Charging

Opportunity charging lets you charge your battery at various intervals during your shift. Image Source: Hangcha

There are basically 3 ways to charge a forklift battery:

- Standard Charging: (16-18% of the battery capacity per hour)

- Opportunity Charging: that charge faster (these chargers generally charge at 25% of the battery capacity per hour). You can charge your battery for shorter periods throughout your shift.

- FAST Charging Options: (these charge up to 40% of the battery capacity per hour but often limit your warranty on the battery as well).

Faster is not always better and the fast charge option should only be used when absolutely necessary as it shortens warranty and wears the battery prematurely in general.

In our experience, standard and opportunity chargers are the best options when combined with good battery brands and efficient forklifts like Linde and Komatsu.

12. Forklift Charging Station Power Requirements

The number of forklifts charging simultaneously will affect your forklift charging area requirements. – Image source: Linde

The power requirements for your forklift charging station are crucial for ensuring efficient and safe operation. Here’s what you need to consider:

Key Factors

Number of forklifts: Determine the number of forklifts needing simultaneous charging to meet your operational needs.

Battery type and size: Lead-acid and Lithium batteries have different charging requirements and amperage demands. Consider individual battery capacities.

Charging speed: Standard or opportunity charging (multiple short charges throughout the day) impacts power requirements.

Charger specifications: Each charger model has specific voltage and amperage ratings. Verify these and their combined demand.

Calculating Power Needs

Identify the total amp-hour (Ah) capacity of all batteries: Multiply individual battery Ah by the number of batteries.

Determine desired charging time: Standard charges take longer, and opportunity charges are faster (needing higher amps).

Use the formula: You can use the following formula to calculate your power needs:

Required Power (kW) = (Total Ah x Desired Charging Time in Hours x Charger Efficiency) / 1000

Additional Considerations

- Safety factor: Add a 20-30% buffer to your calculated power requirement to account for potential future needs or inefficiencies.

- Single or three-phase power: Assess your facility’s existing electrical infrastructure and determine compatibility with your chosen chargers.

- Voltage drops: Consider potential voltage drops due to cable length and resistance, ensuring sufficient power reaches chargers.

- Professional consultation: Consulting a qualified electrician can help accurately assess your specific needs and ensure a safe and efficient power supply for your forklift battery charging station.

Remember: Proper planning and understanding of your power requirements are essential for smooth forklift operations, efficient battery charging, and minimizing potential safety risks. Make sure that you have proper ventilation and heat management in the charging area, especially for high-powered charging setups.

By following these guidelines and seeking professional advice if needed, you can establish a reliable and efficient forklift charging station that meets your business’s needs and ensures the safety and longevity of your equipment.

13. High Efficiency Forklift Battery Charger vs Electric Forklift Battery Charger

The terms “high-efficiency forklift battery charger” and “electric forklift battery charger” might seem interchangeable, but there are subtle differences. Here’s a breakdown to help you choose the right one:

Electric Forklift Battery Charger

An electric forklift battery charger refers to any charger specifically designed for charging electric forklift batteries, regardless of its efficiency level.

- Focus: It primarily charges the battery, without prioritizing energy savings.

- Key features: It will give you the required current and voltage to safely and effectively charge the battery.

- Considerations: This type of charger is a cost-effective option, but your energy consumption might be higher than if you used a high-efficiency charger.

High-Efficiency Forklift Battery Charger

High-efficiency lift truck battery chargers are designed to charge the battery while minimizing energy waste and optimizing efficiency.

- Focus: This type of charger prioritizes low energy consumption and reduced operating costs alongside safe and effective charging.

- Key features: They are equipped with advanced technologies like regenerative braking, power factor correction, and multi-stage charging algorithms to save energy.

- Considerations: You will need to pay a higher initial price than standard chargers, but your savings on energy bills can offset the price over time.

Choosing the Right Option

Consider your budget: If upfront cost is a major concern, a basic electric charger might be suitable.

Energy consumption matters: If your operation prioritizes sustainability and reducing energy costs, a high-efficiency charger offers long-term savings.

Charging needs: Standard chargers work well for traditional setups, while high-efficiency models benefit operations with frequent opportunity charging.

Seek expert advice: Consulting a material handling professional can help assess your specific needs and recommend the most suitable charger.

Remember: Both types of chargers fulfill the basic function of charging your forklift batteries. However, “high efficiency” indicates an added focus on energy savings and cost reduction, making it a valuable consideration for environmentally conscious and cost-effective operations.

If efficiency is a concern you can also consider other energy-saving strategies besides using high-efficiency chargers, such as optimizing charging schedules and utilizing opportunity charging when feasible. By understanding the difference and considering your specific needs, you can make an informed decision when choosing the right forklift battery charger for your operation.

14. Benefits of a Lithium-ion Forklift over a Lead-Acid Forklift

Learn more about the great advantages of Lithium-Ion Technology.

The material handling industry is experiencing a significant shift, with lithium-ion forklift technology rapidly replacing traditional lead-acid batteries. While both options have their place, the advantages of lithium-ion are becoming increasingly undeniable. Here’s a deep dive into the benefits that could transform your operations:

Performance Powerhouse

Faster charging: Lithium-ion batteries charge significantly faster (sometimes in hours) compared to lead-acid overnight charging, minimizing downtime and maximizing productivity.

Longer lifespan: Lithium-ion batteries boast up to 2-3 times the lifespan of lead-acid, reducing replacement frequency and costs.

Sustained power: Experience consistent performance throughout the discharge cycle, eliminating the “voltage sag” of lead-acid batteries and maintaining optimal power delivery.

Improved efficiency: Lithium-ion’s higher energy density translates to more work per charge, reducing energy consumption and operating costs.

Operational Efficiency

Opportunity charging: Take advantage of short breaks throughout the day for top-up charges, keeping forklifts operational without dedicated charging periods.

Reduced maintenance: Forget frequent watering and acid level checks associated with lead-acid batteries. Lithium-ion requires minimal maintenance, saving time and resources.

Smaller footprint: Lithium-ion batteries are often lighter and compact, allowing for smaller, more maneuverable forklifts in space-constrained areas.

Environmental Impact

Eco-friendly: Lithium-ion batteries eliminate the environmental hazards associated with lead acid, including toxic lead and acid spills.

Reduced CO2 emissions: Lower energy consumption and optimized efficiency translate to a smaller carbon footprint and more sustainable operations.

Sustainable future: Choosing lithium-ion aligns your business with evolving sustainability practices and environmental regulations.

Additional Advantages:

- Safety: Lithium-ion batteries are inherently safer, with no flammable gasses or acid leaks.

- Reduced noise: Enjoy a quieter working environment for operators and surrounding areas.

- Better resale value: Lithium-ion forklifts generally hold their value better due to their longer lifespan and advanced technology.

Investment Considerations

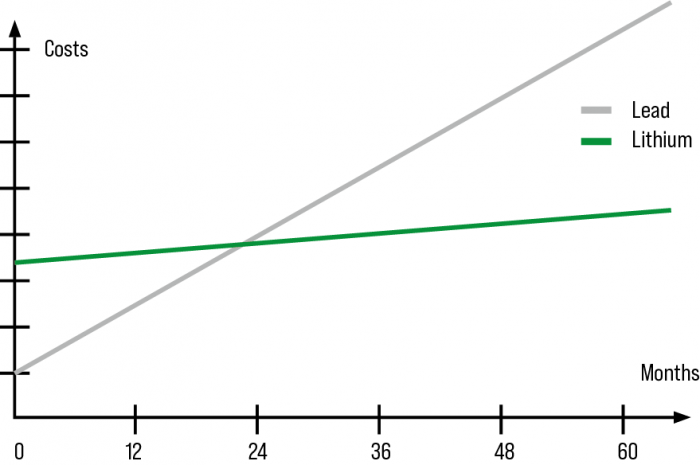

While the initial cost of lithium-ion forklifts is typically higher than lead-acid counterparts, the long-term benefits often outweigh the upfront investment.

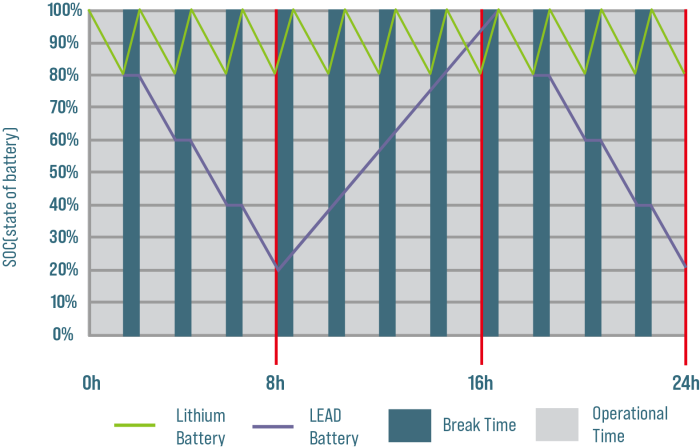

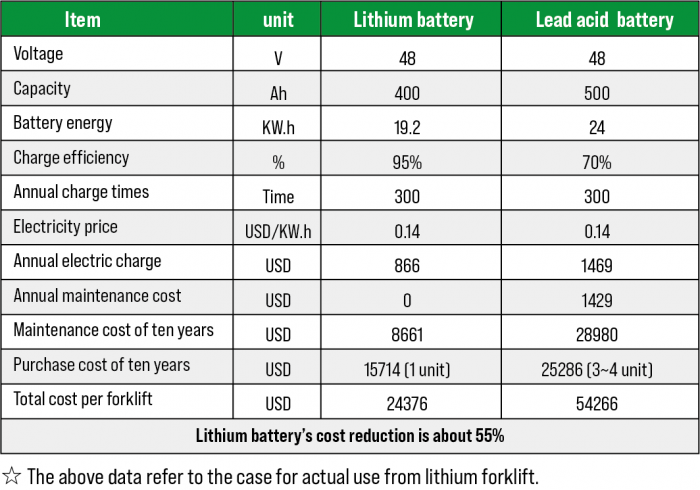

For example, the lithium-ion product line from Hangcha Group makes up for it with a cost reduction of about 55% when compared to a lead-acid battery as the following charts demonstrate:

Total Cost of Ownership Comparison Charts

Image source: Hangcha

Consider the savings in:

- Reduced energy costs: Lower energy consumption and minimized charging time translate to significant financial savings over time.

- Decreased maintenance: Elimination of routine maintenance for watering and acid levels translates to labour and material cost savings.

- Enhanced productivity: Faster charging and sustained power output ensure minimal downtime and maximized productivity.

- Extended battery lifespan: Fewer battery replacements due to the longer lifespan of lithium-ion batteries.

The Choice is Clear

Lithium-ion technology is revolutionizing the forklift industry, offering significant advantages in performance, efficiency, environment, and safety. While the initial cost might be higher, the long-term benefits and return on investment make a strong case for switching to lithium-ion forklifts.

Ready to make the switch? Consult with experts and explore the various lithium-ion options available to find the perfect solution for your operation. This investment can truly transform your efficiency, sustainability, and bottom line.

Interested in a Forklift Battery Charger?

If you are in the market for a forklift battery charger, contact us. Our knowledgeable staff can help you choose the perfect one for your needs.

Since 1977, Ri-Go Lift Truck has been serving customers in Ontario and Quebec with everything they need for material handling. We are committed to providing you with quality service and a high level of customer satisfaction.

We are your authorized dealer for the following top brands:

- Linde Lift Trucks, Power Pallet Trucks, Tow Tractors and Stackers

- Blue Giant Lift Trucks and Pallet Movers

- Komatsu Forklifts and Reach Trucks

- Mariotti Lift Trucks – The Worlds Smallest Lift Truck

- Baoli Lift Trucks

- Advance Sweepers and Scrubbers

- Skyjack Genie Booms and Scissor Lifts

We are also proud to offer you the full lineup of Hangcha forklifts!

In addition to our authorized distributorships, we can also provide you with:

- Large selection of used forklifts

- Operator Training Department – open 7 days a week

- Parts Departments – over 1.4 million dollars of parts on hand for all makes and models

- Service Department – highly trained technicians

- Leasing and Rentals

No matter what your material handling needs are, we can help. Contact us today to let us know how we can be of service.

What Our Customers Think…

“Over 20 years doing business with Ri-go, in maintaining and renting us industrial power equipment. A big business with a real family way of treating the customers. They are experts in the industries they are involved in, and have been an important supplier for me for years. Moving forklifts, installing battery hoists, repairs, etc. If it’s something they don’t normally do, they make the effort to find us someone who can. Very very happy with everyone at Ri-Go.”

– Paul Heggie