Forklift load centres play a crucial role in ensuring safe and efficient lift truck operation. Understanding this concept can help you select the right size forklift for your needs and prevent accidents and product damage. In this blog post, we’ll break down the basics of load centers and provide practical tips for maximizing your forklift’s performance. Click on the following sections to learn more:

- Forklift Load Centres – A Quick Overview

- How Forklifts Work – The Teeter Totter Comparison

- How Does the Load Centre Affect Your Forklift

- Where Are Load Centres Located?

- Are Forklift Load Centres Always 24″?

- What Things Can Increase Your Load Centre?

- How Do You Calculate Your Lifting Capacity if Your Load Centre Isn’t 24″

- Important Load Centre Tips

If you are looking for advice in choosing the right forklift to purchase or rent, ask the experts at Ri-Go Lift.

Forklift Load Centres – A Quick Overview

A forklift load center is the distance from the vertical part of the forks and the center of gravity of the load. The center of gravity is an imaginary point where the weight of an object is concentrated. If you were to put the load in the center of a teeter totter – the load center would be the point on the load right where the teeter totter is perfectly balanced. For a Perfectly balanced or Uniform load that is 48″ long – then the Load Center is 24″ – but often loads are not uniformly distributed. If more of the weight of a 48″ long load is closer to the forklift – then the load center could be less than 24″ – and conversely if more of the weight of the load is farther away from the forklift – then the load center could be more than 24″ – this is where we must be very careful. The farther out the load center is away from the forklift – the heavier the load will feel – and it may require a larger forklift to lift the load.

While most forklifts are rated for a 24-inch load center, this can vary depending on the type of load being handled. To calculate the lifting capacity of your forklift with a different load center, use this formula:

Rated load centre ÷ Actual load centre x Rated capacity of the lift

(so if the normal capacity of the forklift is at a 24″ load center as it is for most forklifts – but if you want to see how much your 6000 lbs. Nominal capacity forklift can lift at a 48″ load center because you want to see if it can lift a uniformly distributed load that is 96″ long) – the formula would be 24 / 48 x 6000 = 3000 lbs – so your forklift can lift 3000 lbs. at 48″ load center – if the load is heavier than that then DO NOT use that forklift – you will need a larger capacity one.

Understanding load centers is crucial for forklift safety. If the weight of your load exceeds the forklift’s load center rating, it can tip over. You can find the load center rating and the associated capacity on the forklift’s data plate. Neither of these numbers is enough on its own – you need to know BOTH the truck capacity AND the rated load center to be sure you are using the right forklift to lift the load safely.

2. How Forklifts Work – The Teeter Totter Comparison

Think of how a teeter totter works when trying to learn how forklift load centres work.

To grasp the concept of a forklift load center, let’s simplify it using a familiar analogy: the teeter totter. A teeter-totter has a pivot point in the center that balances its two riders (or 2 weights) seated on either end.

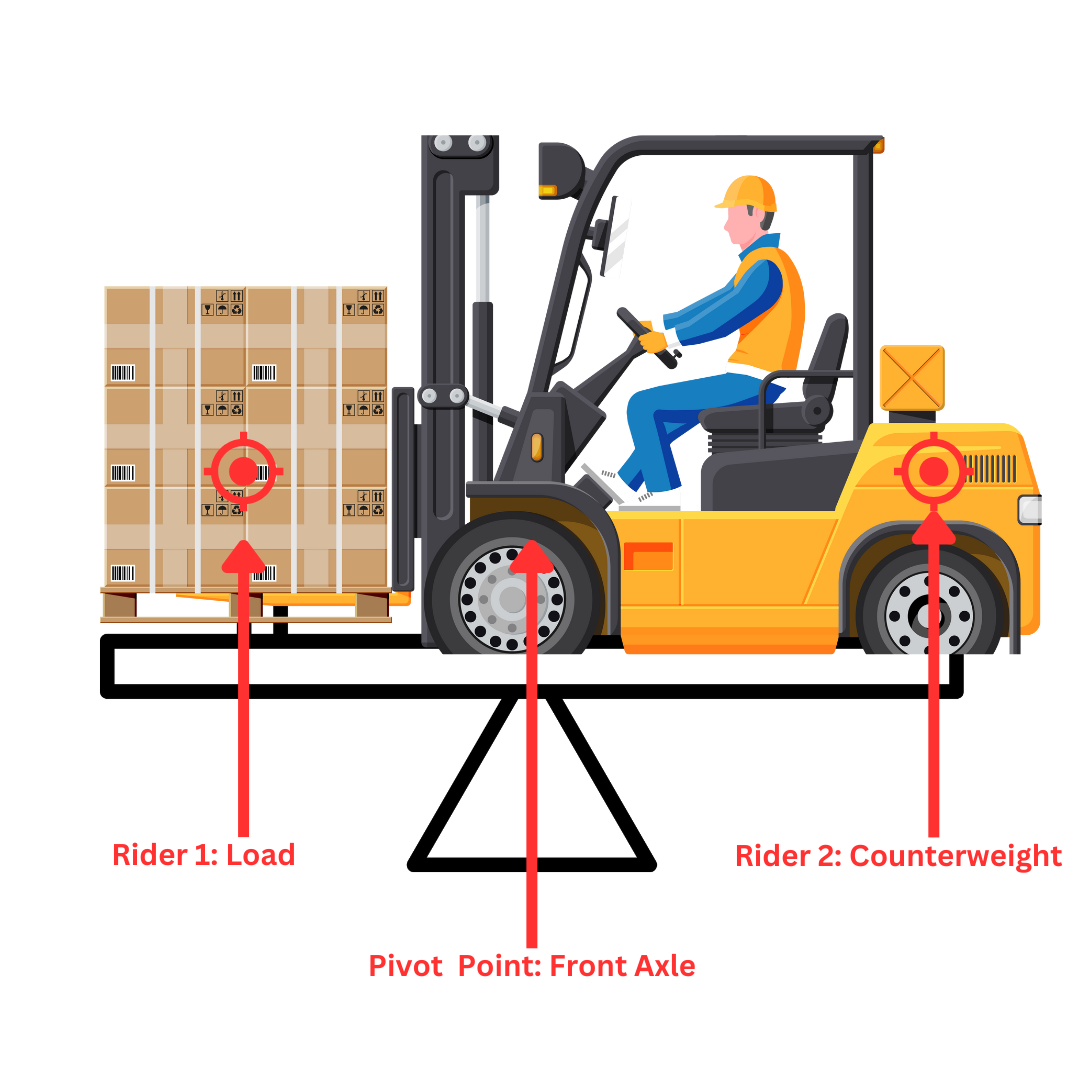

A forklift operates much like a teeter-totter, balancing two “riders” around a pivot point, only instead of balancing two people, the pivot point on a forklift is balancing the forklift’s counterweight and the load that it is lifting:

- Pivot Point: The front axle of the forklift

- Rider 1: The counterweight

- Rider 2: The load being lifted

By understanding this simple principle, we can delve deeper into the importance of load centre in forklift safety and efficiency.

3. How Does the Load Centre Affect Your Forklift

In a loaded forklift, the counterweight’s job is to balance the load on the forks. If the counterweight isn’t heavy enough, or if it is not far back enough from the Pivot point – your forklift can tip over.

So, how does a forklift become overloaded?

The most straightforward way is by placing more weight on the forks than the counterweight can counterbalance. This is like trying to balance a 120-pound person against a 220-pound person on a teeter totter—it simply won’t work.

However, overloading isn’t just about the weight. Another way to overload a forklift is by increasing the distance between the load and the pivot point.

This is where the concept of the load centre becomes critical.

What Is the Load Centre of Your Forklift and What Dimension Defines It?

The Occupational Safety and Health Administration (OSHA) define the load centre as:

“…the distance from the face of the forks to the load’s centre of gravity.”

Key Concepts:

Load Centre:

The following diagram illustrates what the forklift load centre is:

The load centre is the distance from the face of the forks to the load’s centre of gravity.

The load centre is measured from the fork face, which is the vertical part of your forks, to the load’s centre of gravity, indicated by the red bullseye in the above diagram.

Forklift Centre of Gravity:

What is meant by the forklift centre of gravity? The centre of gravity is the point where an object’s weight is evenly balanced.

Unloaded Forklift:

The red bullseye in the following diagram shows where the centre of gravity is located in an unloaded forklift.

The centre of gravity is located just below the operator’s seat.

An unloaded forklift’s center of gravity is approximately below the operator’s seat

Forklift with an Evenly-Distributed Load:

The red bullseye in the following diagram shows the location of the centre of gravity on a forklift with a load that is evenly distributed.

The centre of gravity for a balanced load is at its centre.

For balanced (or uniformly distributed) loads, such as a pallet of bricks or cement blocks, the center of gravity is directly in the center of the load.

When the Forklift is Loaded:

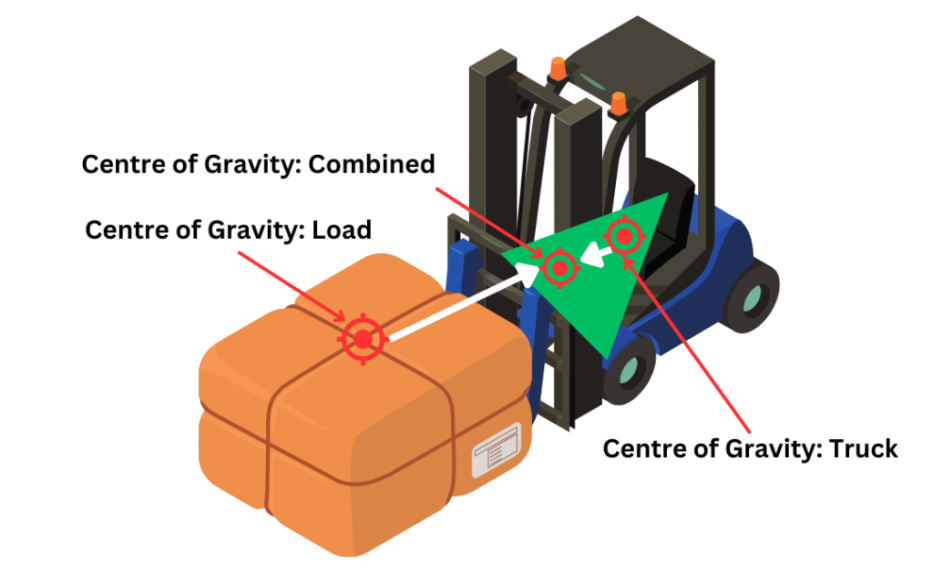

The following image shows what happens when your forklift is loaded.

On a loaded forklift, the centre of gravity moves toward the pivot point.

When your forklift is loaded, the combined centre of gravity shifts toward the forklift’s pivot point. The green triangle in the diagram represents your forklift’s stability triangle. Most forklifts rely on a three-point suspension system for stability. This system comprises the two front wheels and the pivot point of the rear axle. When you mentally connect these three points, you form a triangle, often referred to as the “stability triangle.”

Bringing It All Together:

Using the teeter totter analogy, the relationship between the load centre and centre of gravity determines whether the forklift remains stable. These principles must work in harmony to maintain balance and safety.

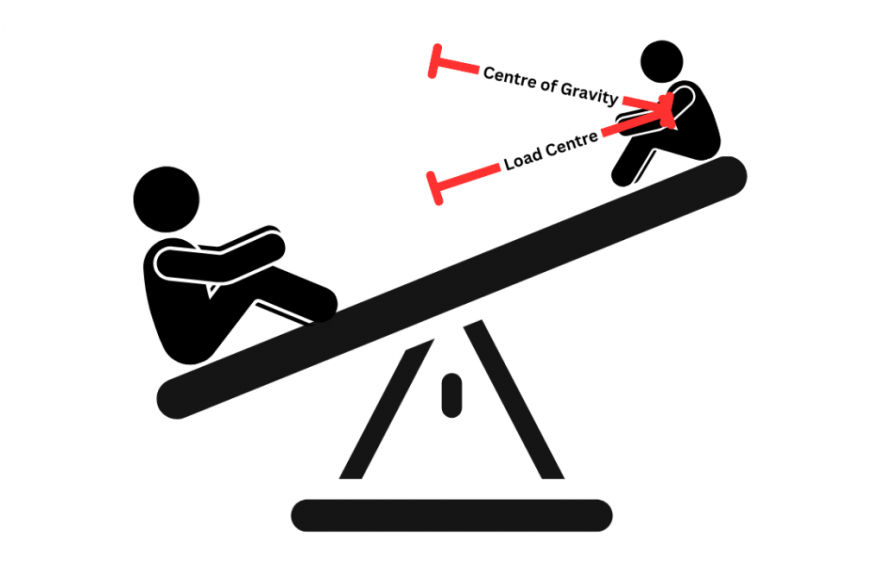

When we sit on a teeter totter, our centre of gravity—the point where our weight is concentrated—is typically around our chest. Now, imagine two people on a teeter totter: a 220-pound person and a 120-pound person. If they sit at equal distances from the pivot point, the teeter totter will balance as in the diagram below.

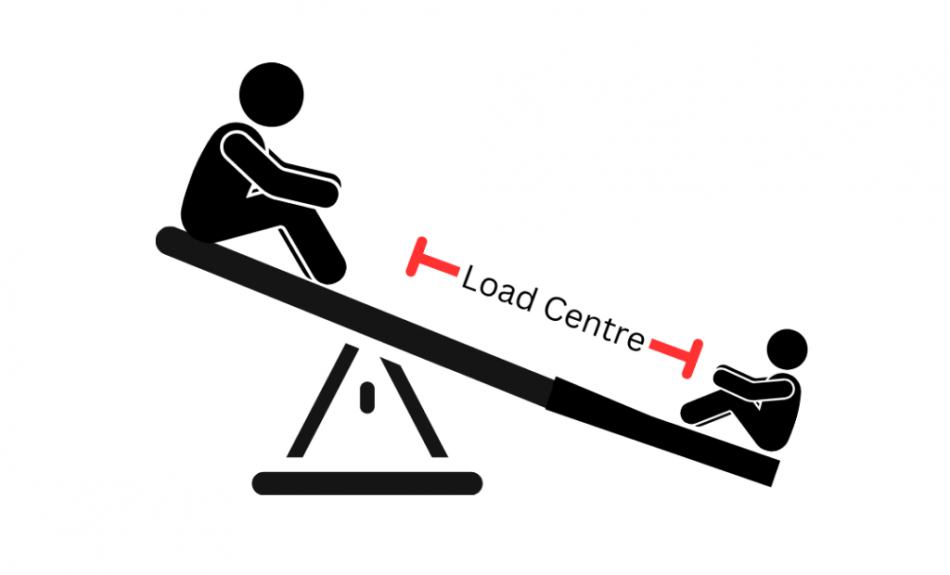

However, if the 120-pound person moves farther away from the pivot point, they can eventually overcome the weight of the 220-pound person and tip the teeter totter as seen in the diagram below.

This concept is directly applicable to forklifts. The distance between the fork face and the centre of gravity of the load is known as the load centre. If the load centre exceeds the forklift’s rated load centre, the forklift can tip over.

Make sure your loads are properly distributed.

To prevent this, it’s crucial to ensure that the load is properly distributed and doesn’t extend beyond the forklift’s rated load centre. By understanding load centres and following safe operating practices, you can significantly reduce the risk of forklift accidents.

4. Where Are Load Centres Located?

Now that you understand the concept of a forklift load centre, you might wonder where to find this information.

The answer lies on your forklift’s data plate, a metal plate affixed to the truck by the manufacturer. This plate contains crucial information, including the load centre rating.

While most forklifts are rated for a 24-inch load centre, it’s important to note that this is a standard rating based on common pallet dimensions. A standard pallet is typically 48 inches long. Assuming the load is evenly distributed on the pallet, the centre of gravity will be at the 24-inch mark. This is why a 24-inch load centre is a common rating for forklifts.

5. Are Forklift Load Centres Always 24″?

Different forklifts have different load centres.

No, the load centre can vary significantly. It’s simply a measurement of the distance between the load’s centre of gravity and the face of the forks.

The specific load centre rating of a forklift depends on its design and intended use. For instance, forklifts designed to handle long loads may have load centre ratings of 30 or even 60 inches.

6. What Things Can Increase Your Load Centre?

Adding forklift attachments can greatly increase your forklift load centre.

It’s crucial to recognize that adding attachments like sideshifters, fork positioners, or clamps can significantly increase a forklift’s load centre. This occurs because the attachment’s thickness effectively extends the distance between the fork face and the load’s centre of gravity.

This increased distance, known as the load moment, can potentially destabilize the forklift. Consequently, any forklift equipped with an attachment must have an updated data plate.

This updated plate will specify the type of attachment and provide revised load centre and lifting capacity ratings to ensure safe operation.

7. How Do You Calculate Your Lifting Capacity if Your Load Centre Isn’t 24″

You can calculate your lifting capacity using the formula below.

Before diving into calculations, it’s crucial to always consult the original equipment manufacturer (OEM) for accurate capacity ratings.

Understanding load centres is essential for safe and efficient forklift operation. It helps operators determine if a forklift can safely lift a specific load. While standard calculations work for evenly distributed loads, real-world scenarios often involve irregular loads with varying centres of gravity.

Calculating Load Capacity

To determine the lifting capacity of a forklift for irregular loads, use the following formula:

Rated Load Centre ÷ Actual Load Centre × Rated Capacity of the Lift = Lifting Capacity

Breaking Down the Calculation:

Rated Load Centre: Found on the forklift’s data plate, typically 24 inches.

Actual Load Centre: Measured distance between the fork face and the load’s centre of gravity.

Rated Capacity: The maximum weight the forklift can lift at its rated load centre.

Example Calculation:

Rated Load Centre: 24 inches

Actual Load Centre: 30 inches

Rated Capacity: 4,000 lbs.

Calculation: 24 ÷ 30 × 4,000 = 3,200 lbs.

In this scenario, the forklift can safely lift 3,200 lbs. at a 30-inch load centre.

A Final Reminder:

While these calculations provide a basic understanding, always prioritize safety and consult the OEM’s certified capacity ratings. Avoid making independent calculations and strictly adhere to manufacturer guidelines and safe operating procedures.

8. Important Load Centre Tips

Always follow safe driving practices.

To maximize safety and efficiency when operating a forklift, consider these essential tips:

Even Load Distribution:

Ensure loads are evenly distributed both vertically and horizontally to prevent tipping.

Place loads as close to the load backrest as possible to minimize the load center and if you have an unevenly distributed load – then it is always best to put the heaviest part of the load as close to the forklift as possible to minimize the Load Center and increase the potential capacity of the forklift.

Attachment Considerations:

Any added attachments, such as side shifters or clamps, can increase the load centre.

Always obtain a new data plate after installing an attachment to reflect the updated load capacity.

Mast Tilt and Load Capacity:

Tilting the mast forward increases the load centre, potentially reducing the forklift’s lifting capacity.

Exercise caution, especially when handling loads near the capacity limit.

Side Shifting Precautions:

Side shifting a heavily loaded forklift can shift the horizontal load centre, increasing the risk of lateral tipping. Proceed with caution and avoid excessive side shifting.

Safe Driving Practices:

You should always follow safe driving practices including:

- Accelerate and brake smoothly.

- Reduce speed when turning.

- Keep the load low to the ground (4-6 inches) for better stability and greater safety.

By following these guidelines, you can significantly reduce the risk of accidents and ensure the safe operation of your forklift.

For the Best Selection of Forklifts – Contact Ri-Go.

If you are in the market for a new or used forklift, contact us. We have a wide selection including reach trucks, and our knowledgeable staff can help you choose the perfect unit for your needs.

Since 1977, Ri-Go Lift Truck has been serving customers in Ontario and Quebec with everything they need for material handling. We are committed to providing you with quality service and a high level of customer satisfaction.

We are your authorized dealer for the following top brands:

- Linde Lift Trucks, Power Pallet Trucks, Tow Tractors and Stackers

- Hangcha – Full Line-up Including Lithium-Ion

- Blue Giant Lift Trucks and Pallet Movers

- Komatsu Forklifts and Reach Trucks

- Mariotti Lift Trucks – The Worlds Smallest Lift Truck

- Baoli Lift Trucks

- Advance Sweepers and Scrubbers

- Skyjack Genie Booms and Scissor Lifts

In addition to our authorized distributorships, we can also provide you with:

- Large selection of used forklifts

- Operator Training Department – open 7 days a week

- Parts Departments – over $1.9 million dollars of parts on hand for all makes and models

- Service Department – highly trained technicians

- Leasing and Rentals

No matter what your material handling needs are, we can help. Contact us today to let us know how we can be of service.

What Our Customers Think…

“Over 20 years doing business with Ri-go, in maintaining and renting us industrial power equipment. A big business with a real family way of treating the customers. They are experts in the industries they are involved in, and have been an important supplier for me for years. Moving forklifts, installing battery hoists, repairs, etc. If it’s something they don’t normally do, they make the effort to find us someone who can. Very very happy with everyone at Ri-Go.” –Paul Heggie