While lead-acid batteries have been the primary choice for electric forklifts for decades, lithium-ion technology offers a compelling alternative. This blog post dives deep into everything you need to know about buying a lithium forklift battery.

We’ll explore the key differences between lithium-ion and lead-acid options, unpack the impressive features and benefits of Lithium-ion, and guide you through essential considerations before making the switch. We’ll even unveil the top lithium-ion battery manufacturers and shed light on the investment involved. Click on each section below to learn more.

- Is a Lithium Forklift Battery Worth the Investment?

- What Is the Difference Between Lithium-Ion and Lead-Acid Forklift Batteries?

- Advantages of a Lithium-Ion Forklift Battery

- Disadvantages of a Lithium-Ion Forklift Battery

- Is a Lithium-Ion Battery the Right Fit for You?

- Converting Your Forklifts to Lithium-Ion

- Lithium Forklift Batteries: Manufacturers, Types, Storage, Maintenance & More

- Lithium Forklift Battery FAQ

- Summary

Looking for assistance in choosing the best lithium forklift battery for your situation? Contact Ri-Go Lift today.

Your Complete Guide to Buying a Forklift Battery

1. Is a Lithium Forklift Battery Worth the Investment?

Lithium forklift batteries are great for multi-shift operations.

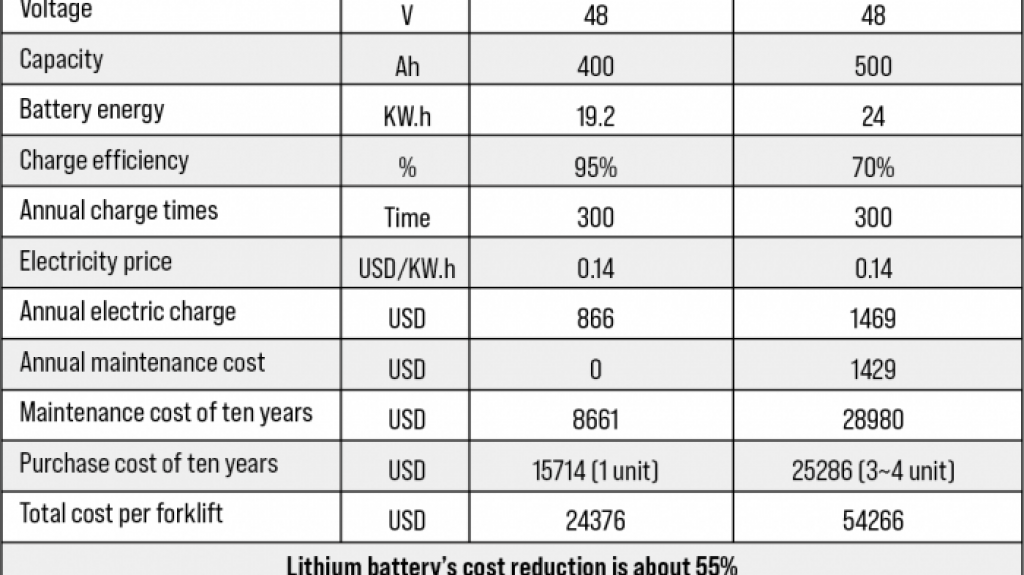

If you operate a medium to large-size business with multiple shifts, lithium-ion forklift batteries could be an excellent choice. Despite their higher initial cost compared to lead-acid batteries, they offer substantial long-term savings.

Here are some key points to consider:

A) Cost Savings:

Although lithium forklift battery prices are currently higher, their overall cost-effectiveness becomes evident over time.

B) Multi-Shift Advantage:

Operations running multiple shifts benefit significantly from switching to lithium-ion batteries.

C) ROI Timeline:

Achieving return on investment (ROI) within 36 months is common for lithium-ion forklift batteries.

D) Energy Efficiency:

Lithium-ion batteries outperform lead-acid batteries, being 40% more energy-efficient overall.

E) Longevity:

Designed for durability, lithium-ion batteries have a longer lifespan, reducing the need for frequent replacements.

F) Cold Tolerance:

These batteries can withstand extremely low temperatures, making them suitable for outdoor use.

2. What Is the Difference Between Lithium-Ion and Lead-Acid Forklift Batteries?

You have two basic choices for batteries for your electric forklift: either lead-acid or lithium-ion. Here is a detailed breakdown of these two very different technologies.

A) Lead-Acid Batteries

The following video goes into detail about how a lead-acid battery works. Read on for a summary of the process.

Lead-acid forklift batteries consist of lead plates submerged in an electrolyte solution.

Lead-acid batteries have been widely used for many years. Their technology dates back to the mid-1800s. Also known as “wet cell batteries,” lead-acid forklift batteries are cost-effective.

The following is a breakdown of lead-acid battery components and how they work. Lead-acid forklift batteries consist of lead plates submerged in an electrolyte solution (a mixture of sulfuric acid and water).

The key components of lead-acid batteries include:

- Cells

- Bars

- Plates made of lead dioxide

- Cables

- Electrolyte

To generate electricity, an electrochemical reaction occurs between the lead plates and the electrolyte solution. The electrical ions flow from the sulfuric acid to the negative plate, resulting in electricity production.

Charging a Lead-Acid Battery

Charging lead-acid batteries takes longer compared to lithium-ion batteries. Typically, this process occurs through conventional charging, often after a shift. During conventional charging, a low current is applied for approximately 8 to 10 hours until the battery reaches full charge. Following this extended charging period, a 6 to 8-hour “cooldown” phase is necessary before using the battery again.

Conventional charging is primarily done overnight and is well-suited for single-shift operations. However, lead-acid batteries do not typically undergo opportunity charging. Doing so can lead to rapid battery damage, accelerated wear, and reduced overall cycle life.

In summary, lead-acid forklift batteries have a shorter lifespan—typically lasting 3 to 5 years (equivalent to 1,000 to 1,500 charging cycles) under normal 40-hour week operations.

B) Lithium-Ion Batteries

The following video goes into great detail about what a lithium-ion battery is and how it works. For a brief summary, read on.

Lithium-ion is quickly becoming the most popular choice for a forklift battery.

Lithium-ion batteries have seen widespread adoption in consumer electronics over the past few decades. Now, they are increasingly becoming the preferred technology for forklifts.

Here are the key components of lithium-ion forklift batteries:

- Cathode

- Electrolyte (lithium)

- Anode

- Separator

- Two current collectors (positive and negative)

To generate electric energy, various chemistries are at play in lithium-ion batteries. Among these, the most popular for forklifts is lithium iron phosphate.

During discharge, the anode and cathode store the lithium. The electrolyte flows from the anode to the cathode through the separator, carrying positively charged lithium ions.

Lithium-ion Battery Charging

When charging, the electrolyte liquid moves from the cathode to the anode through the separator, transporting negatively charged lithium ions.

Lithium-ion batteries excel in opportunity charging due to their fast-charging capability. Specialized chargers with high currents can quickly charge these batteries. Opportunity charging can be done as needed or when it’s most convenient, making lithium-ion batteries highly efficient.

With proper maintenance, a lithium-ion forklift battery can last between 2,000 and 3,000 cycles, equivalent to approximately 7 to 10 years of 300 workdays per year.

3. Advantages of a Lithium-Ion Forklift Battery

Lithium-ion powered forklifts can help improve your efficiency – Image Source: Linde

Lithium-Ion forklift batteries have many great advantages that will help increase your efficiency. Here are the main pros of this incredible technology.

A) Enhanced Productivity with Lithium-Ion Forklift Batteries

Lithium-ion forklift batteries offer several advantages over lead-acid batteries, particularly in terms of charging and performance:

- Opportunity Charging: These batteries can be charged in short 15-30-minute intervals, known as opportunity charging. This flexibility allows you to recharge during lunch breaks or whenever the forklift is idle for a few minutes, supporting multi-shift operations. While you can opportunistically charge a lead-acid battery, it shortens the battery life.

- Improved Runtimes: The most significant benefit of lithium-ion forklift batteries is their ability to dramatically enhance runtimes. They outperform lead-acid batteries in terms of longevity on a single charge.

- Flatter Discharge Curve: Unlike lead-acid batteries with a linear discharge curve, lithium-ion batteries exhibit a flatter curve. This means that even when nearly fully discharged, the voltage at the battery terminals remains relatively stable, allowing the battery to retain more power.

- State-of-Charge (SoC) Considerations: Lithium-ion batteries can be safely used up to beyond 80% state-of-charge (SoC), but not down to zero. Fully discharging them may cause damage.

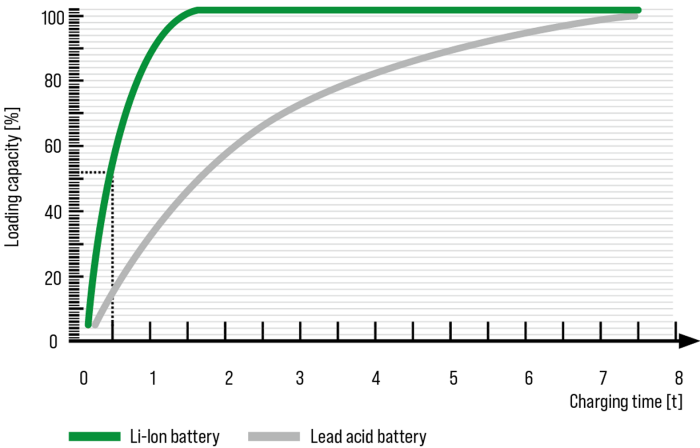

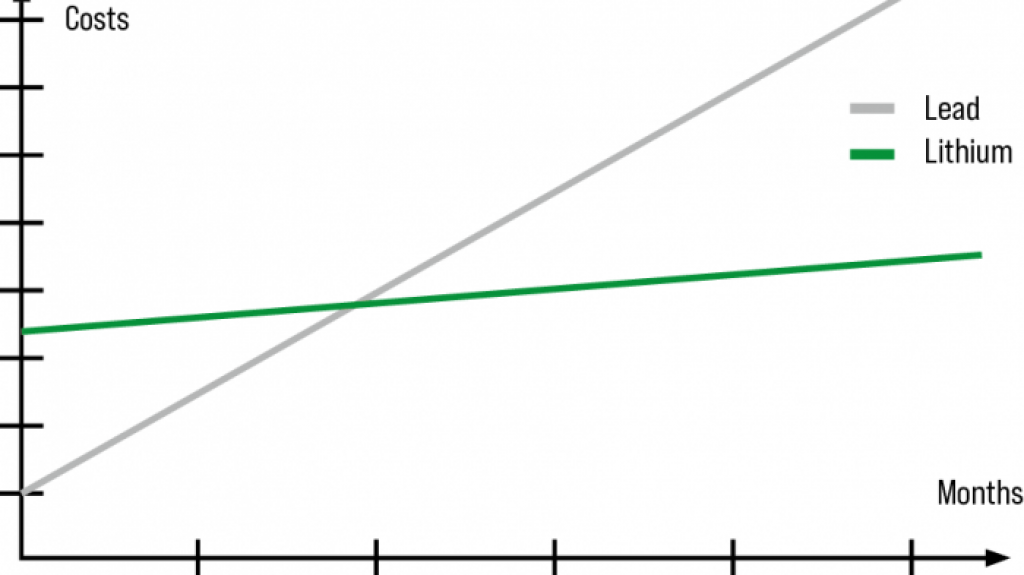

- Fast Charging: Lithium-ion batteries can achieve a full charge in less than 2 hours, without requiring a cooling-off period like lead-acid batteries. The grey line on the graph below shows the more traditional lead-acid battery charge curve and it is a much more gradual curve. This shows that lead-acid batteries take longer to fully charge, typically several hours.

Charging Times: Lithium vs Lead-Acid

Faster charging times mean that lithium forklift batteries are ready to go when you need them. Image source: Hangcha

By adopting lithium-ion technology, your fleet can benefit from reduced downtime and increased productivity and throughput.

B) Greater Efficiency and Energy Storage

A lithium-ion forklift battery is much more energy efficient than a lead-acid battery, so it can help you reduce your energy costs. Here’s why.

Lead-Acid:

Lead-acid batteries lose energy during discharge, charging, or idle periods, resulting in only approximately 80% of the input energy being available as output. This inefficiency contributes to higher electricity costs.

Lithium-Ion:

In contrast, lithium-ion batteries exhibit greater energy efficiency due to minimal losses. They retain most of the energy used for charging, sometimes up to 99%, resulting in reduced electricity costs. A single lithium-ion battery can power three shifts due to its efficiency.

In addition, lithium-ion batteries store 4 times more energy and are 30% more energy-efficient compared to lead-acid batteries.

C) Lithium-Ion Batteries Require Much Less Maintenance

Similar to maintaining your forklifts, your forklift batteries also require regular upkeep.

Lead-Acid:

For lead-acid batteries, improper maintenance can lead to a chemical process called battery sulfation, resulting in breakdown. To keep them healthy, you must monitor water and electrolyte levels, regularly topping up with distilled water. However, this maintenance can be time-consuming and costly.

Lithium-Ion:

In contrast, lithium-ion batteries demand minimal maintenance. Lithium-ion batteries don’t need water topping or frequent procedures like equalizing charging and cleaning. Their sealed cells eliminate the need for washing or water addition, reducing labour and costs. Additionally, Li-ion batteries can remain inside the forklift throughout the workday, eliminating the need for battery removal or swaps.

This streamlined maintenance approach also saves space by eliminating watering and maintenance areas.

D) Great for Multi-Shift Applications

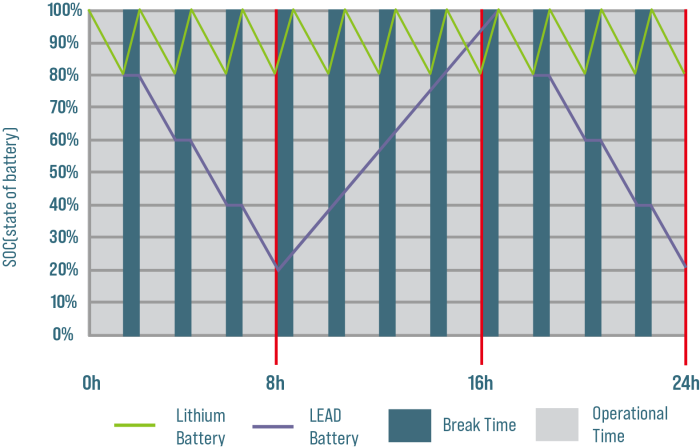

For continuous 16 or 24-hour operations, efficient battery charging is essential.

The key difference lies between lead-acid forklift batteries and lithium-ion forklift batteries:

Lead-Acid Batteries:

- Requires approximately 8 hours to charge.

- Need an additional 8 hours of cooling time.

- Total downtime before reuse: around 16 hours.

- Multi-shift operations may necessitate 2 to 3 lead-acid batteries per forklift.

Lithium-Ion Batteries:

- Fully charge in 2 hours or less.

- No cooling-off period is required.

- Supports multi-shift operations with just 1 battery per forklift.

- Opportunity charging (15-30-minute spurts) is possible.

How Opportunity Charging Works

Lithium batteries can be recharged at any time without having a complete discharge first. – Image source: Hangcha

Unlike lead-acid batteries, Li-ion batteries do not experience the “memory effect.” This means they can be recharged at any time without requiring a complete discharge first. This type of continuous charging is called “opportunity charging.” With opportunity charging, forklifts can be charged during short breaks or downtime, ensuring continuous operation and maximizing productivity.

Therefore, if you use lead-acid forklift batteries you may need 2 to 3 lead-acid batteries per forklift, but if you use lithium-ion forklift batteries, you will just need 1 forklift battery per forklift.

E) Enhanced Safety

Forklift battery safety plays a critical role in overall forklift operation. Many battery-related incidents occur during battery movement or watering procedures.

Lead-acid batteries, composed of two high-risk chemicals—sulfuric acid and lead—pose safety hazards for both operators and the environment. Sulfuric acid exposure can cause skin or eye burns, necessitating personal protective equipment (PPE) such as

- Splash-proof goggles

- Acid-resistant aprons

- Face shields

- Rubber gloves

Additionally, lead-acid batteries are highly explosive, especially during charging, particularly if the charging area lacks proper ventilation. Installing hydrogen sensors in lead-acid battery storage and charging rooms is recommended as a precautionary measure.

In contrast, lithium-ion forklift batteries offer distinct advantages including:

- Lithium-ion batteries are significantly safer than lead-acid batteries, with fewer health risks.

- They are fully sealed, eliminating the need for operators to access the battery compartment for watering. This reduces the risk of electrolyte spills, toxic fumes, and sulfation associated with lead-acid batteries.

- No PPE is required during battery maintenance, contributing to cost savings and improved warehouse safety.

Temperature Control:

Unlike lead-acid batteries, lithium-ion batteries do not overheat. Their temperature typically increases by only 5 to 6 degrees during operation.

F) Requires Less Charging Equipment

When utilizing lead-acid batteries, it may be necessary to use multiple batteries per forklift during operations. This practice can also impact storage space requirements.

Additionally, ensuring a safe storage environment involves keeping batteries away from hot air ducts, direct sunlight, and other heat sources while maintaining proper ventilation. Adhering to a secure charging process is crucial to prevent acid spills or leaks that could cause burns, corrosion, and other hazards.

In contrast, lithium-ion batteries offer simplicity in charging and minimal maintenance. Unlike lead-acid batteries, they do not necessitate additional storage infrastructure, as a single battery per forklift is all that you will need.

G) Greater Return on Your Investment

A lithium-ion forklift battery will outlast a lead-acid battery, so it will give you a greater return on your investment.

Lifespan Comparison:

- Under proper maintenance, a lead-acid battery typically lasts around 1,500 cycles.

- In contrast, a lithium-ion forklift battery can endure between 2,000 and 3,000 cycles.

- Intermittent charging (e.g., 15 to 30 minutes) does not diminish the lifespan of Li-ion batteries, unlike lead-acid counterparts.

Return on Investment Considerations:

Running lithium-ion batteries in a forklift for 3,000 hours annually can yield an ROI in less than 36 months.

Here’s why:

- No need to purchase extra batteries for changeovers due to rapid charging (opportunity charging), saving space.

- Fewer charging stations are required, as lithium-ion chargers are compact compared to lead-acid chargers.

- Opportunity charging during short breaks maintains battery health without causing damage.

- Reduced downtime and 4X longer lifespan enhance fleet efficiency.

4. Disadvantages of a Lithium-Ion Forklift Battery

The initial purchase price is higher for lithium forklifts; however, the total cost of ownership is usually much lower.

While lithium-ion forklift batteries offer distinct advantages, it’s essential to consider potential drawbacks.

A) Higher Initial Purchase Price

The primary drawback of lithium-ion batteries lies in their cost. When acquiring a lithium-ion forklift battery, you can expect to pay approximately $17,000-$20,000 per battery on average. Comparatively, the upfront expense for a lead-acid battery is lower, often less than half the initial investment required for a lithium-ion forklift battery.

However, the total cost of ownership is usually much lower for a lithium-ion forklift when you consider the lower energy used to charge it, the lower maintenance costs, the longer lifespan, and less equipment required.

B) Higher Input Current Needed

Due to faster charging, Li-ion batteries necessitate higher input currents. Consider conducting an energy audit at your facility to assess whether you need to upgrade your electrical infrastructure for efficient Li-ion forklift battery charging. Keep in mind that this transition will involve a significant one-time cost.

C) Disposal Risks

Improper handling of lithium-ion batteries can pose various risks and hazards. To safely recycle a lithium-ion forklift battery, it must undergo a series of safety protocols. Consider collaborating with local forklift dealers, such as Ri-Go Lift, to identify the appropriate disposal location for your lithium-ion forklift battery.

5. Is a Lithium-Ion Battery the Right Fit for You?

A lithium battery forklift makes sense for many types of applications.

When you are running a material handling operation, you understand that achieving efficiency and productivity is crucial for success. That’s because time is a finite resource. Therefore, any opportunity to accomplish more within less will give you a competitive edge. Now, let’s explore whether a lithium forklift battery can provide you with precisely that huge advantage.

A) Are you operating multiple shifts?

Industries such as manufacturing, third-party logistics (3PL), food processing, and other 24/7 material handling operations derive significant advantages from using lithium-ion batteries. These operations can utilize just one lithium-ion battery per forklift truck. The primary benefit of transitioning to lithium-ion forklift batteries in busy multi-shift environments is evident.

Interestingly, their only regret is not making the switch sooner. For multi-shift operations, lithium-ion batteries may achieve a return on investment (ROI) in as little as 36 months. In contrast, single-shift operations might experience a longer ROI timeframe—around 5 years or more.

B) Is your facility equipped with a freezer or cold storage environment?

Lead-acid batteries exhibit poor performance in cold conditions, with their capacity potentially decreasing by up to 35%. In contrast, lithium-ion forklift batteries maintain their capacity much more effectively in cold temperatures compared to lead-acid batteries. Additionally, lithium-ion batteries can be fast-charged even within freezers.

Therefore, operations that involve forklifts operating in cold or freezing environments can significantly benefit from adopting lithium-ion forklift batteries.

C) Are you operating on tight margins?

If your operations are characterized by tight margins, consider transitioning to lithium-ion forklift batteries. Why?

By making the switch, you can achieve several immediate benefits, including:

- Reduced energy bills

- Reclaimed real estate

- Improved productivity

Lithium-ion forklift batteries exhibit impressive energy efficiency—up to 40% more efficient than lead-acid batteries and a remarkable 88% more efficient than diesel.

While lead-acid forklift batteries may have a lower upfront cost, they ultimately prove more expensive to own and maintain. Prioritizing increased productivity and lower energy expenses, adopting lithium-ion forklift batteries becomes a strategic choice.

6. Converting Your Forklifts to Lithium-Ion

You can convert your current forklifts to lithium. – Image Source: Hangcha

Transitioning from lead-acid to lithium-ion batteries doesn’t involve any special requirements. The only retrofit necessary is installing a new Li-ion battery onto the forklift and adding a charge meter to your charging area. However, before, during, or after the lithium forklift battery installation, there are some important considerations that you need to keep in mind.

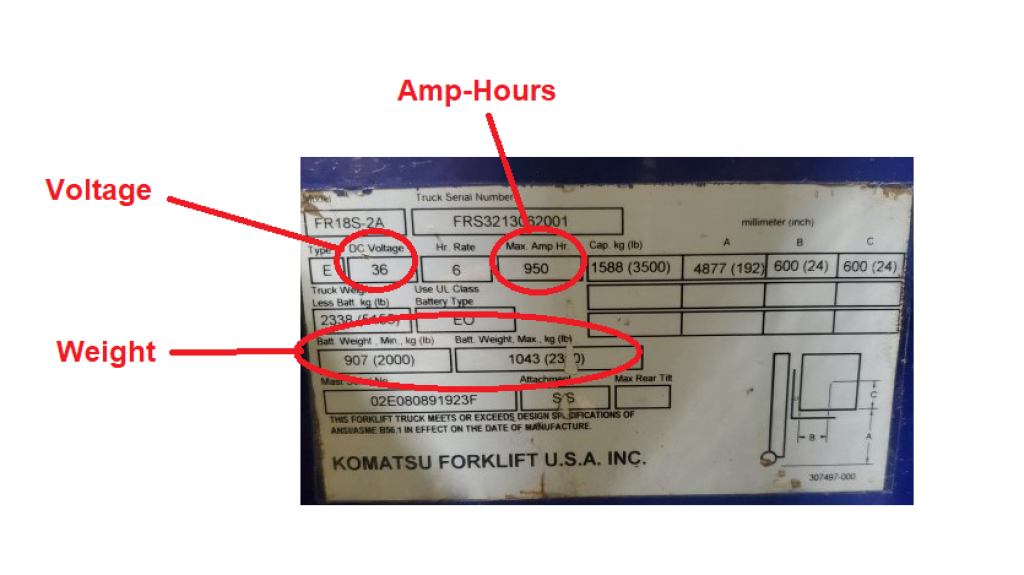

A) Check the Weight of the Battery

Many counterbalanced forklifts factor in the battery’s weight when determining load capacity. However, with a lighter lithium-ion battery, you might need to add counterweights to maintain the forklift’s specified capacity. Additionally, consider adjusting the lifting capacity to account for the weight of the new Li-ion battery. For further information on forklifts, explore the Toyota Forklift Models: The Complete Guide

B) Check the Voltage

Ensure you verify and, if necessary, adjust the charge voltage of the forklift’s battery bank. A low charge voltage can leave the batteries incompletely charged, while an excessively high voltage may push a lithium-ion battery beyond its safe operating limits.

Additionally, opt for shunt-based battery monitoring rather than voltage-based methods. Here’s the significance:

Voltage Measurement vs. Shunt-Based Monitoring:

Some battery monitoring systems rely on voltage measurements to assess battery status. However, for lithium-ion batteries, this approach can yield unreliable readings, potentially leading to deep discharges.

Instead, choose shunt-based (ampere-hour counting) monitoring devices. Shunt-based monitoring provides more accurate data and helps maintain battery health. Ensure that the monitoring device includes a specific setting for the Lithium battery type.

C) Check the Amp-Hours

Amp-hours quantify a battery’s electrical output. Not all batteries share the same amp-hour capacity, and different forklift models demand varying amp-hour levels. Ensuring alignment between lithium-ion and forklift amp-hours is crucial.

Check your forklift’s data plate for the weight, voltage, and amp-hours.

D) Train Your Operators

To optimize the lifespan and utilization of your Lithium-ion forklift battery, implement a comprehensive opportunity charging program for your operators. This entails ensuring operators plug the battery into a charger whenever the forklift is idle for any significant period.

7. Lithium Forklift Batteries: Manufacturers, Types, Storage, Maintenance & More

Lithium Forklift Battery Manufacturers

There are many top lithium forklift battery manurfacturers. – Image Source: Hangcha

Here’s a list of the top 10 lithium forklift battery manufacturers, along with a brief description of each company:

- Electrovaya (Canada): A pioneering company in lithium-ion battery technology, Electrovaya offers a wide range of lithium forklift batteries known for their durability, performance, and safety.

- Flux Power (United States): Specializes in designing, developing, and manufacturing high-performance lithium-ion battery packs for industrial applications, including forklift trucks. Flux Power batteries are known for their rapid charging capabilities and long lifespans.

- Green Cubes Technology (China): A leading manufacturer of lithium batteries for electric vehicles and industrial applications, Green Cubes offers a comprehensive selection of forklift battery solutions designed for various needs and budgets.

- Navitas Systems (United States): Specializes in clean, electric power solutions, including lithium-ion batteries for forklifts. Navitas batteries are known for their eco-friendly design and efficient operation.

- OneCharge (United States): Provides a variety of lithium-ion battery solutions for industrial applications, including forklift trucks. OneCharge batteries are known for their innovative design and reliable performance.

- CATL (China): A global leader in lithium-ion battery technology, CATL offers a wide range of battery solutions for electric vehicles and industrial applications, including forklift trucks. CATL batteries are known for their high energy density and long lifespans.

- Pcenersys (China): A leading manufacturer of lithium-ion batteries for electric vehicles and industrial applications, Pcenersys offers a comprehensive selection of forklift battery solutions designed for various needs and budgets.

- Eikto (China): Specializes in the development and manufacturing of lithium-ion battery packs for electric vehicles and industrial applications, including forklifts. Eikto batteries are known for their advanced technology and safety features.

- Gotion (China): A leading manufacturer of lithium-ion batteries for electric vehicles and industrial applications, Gotion offers a wide range of battery solutions for forklift trucks. Gotion batteries are known for their reliability and performance.

- CNTN (China): Specializes in the research, development, manufacturing, and sales of lithium-ion batteries for electric vehicles and industrial applications, including forklifts. CNTN batteries are known for their innovative design and efficient operation.

It’s important to note that this is not an exhaustive list, and there are many other reputable lithium forklift battery manufacturers around the world. When choosing a lithium forklift battery manufacturer, it’s important to consider your specific needs and budget, as well as the reputation and warranty of the company.

Types of Lithium-Ion Forklift Batteries

Lithium Iron Phosphate (LiFePO4) is the most common lithium forklift battery. – Image Source: Linde

Within the lithium-ion forklift battery market, several options exist, differentiated by the cathode material employed. Common choices include:

Lithium Iron Phosphate (LiFePO4) has emerged as the dominant lithium forklift battery technology due to its superior safety characteristics, ability to handle high currents, and reduced environmental impact compared to other lithium-ion chemistries.

Sizes of Lithium-Ion Forklift Batteries

Selecting the appropriate lithium battery size is crucial for ensuring your forklift operates at peak capacity. Forklift battery sizes vary depending on several factors such as the lift truck’s dimensions, brand, manufacturer, and specific model.

Generally, a positive correlation exists between the size of the forklift and the required battery size. In many instances, the battery’s nameplate will clearly display the size. If this information is unavailable, the cell connectors near the positive terminal can be checked to find the model number, serial number, and weight specifications.

It’s important to consider the compatibility of the lithium forklift battery weight with the specific forklift model during the selection process. Forklift battery weights typically range from 600 lbs. for smaller models to exceeding 5,000 lbs. for the largest electric lift trucks.

Key Specs of Lithium-Ion Forklift Batteries

Equipping your forklift with the most suitable lithium-ion battery requires careful consideration of several key specifications:

- Forklift Compatibility: Ensure the battery is designed for your specific forklift class (e.g., Class I, II, III).

- Charging: Identify the appropriate charging duration and compatible charger type.

- Capacity & Output: Evaluate the battery’s Amp-hour (Ah) rating, reflecting its capacity and output capabilities.

- Voltage: Determine the required battery voltage to match your forklift’s electrical system.

- Physical Specifications: Consider the battery compartment size limitations and ensure the weight and counterweight are compatible with your forklift model.

- Environmental Factors: Select a battery suitable for your operating conditions, including extreme temperatures (freezing or high-heat environments).

- Power Delivery: Evaluate the battery’s rated power to ensure it meets the power demands of your forklift applications.

- Manufacturer Reputation: Choose a reputable lithium-ion battery manufacturer with a proven track record.

- After-Sales Support: Prioritize a manufacturer offering comprehensive support, service, and warranty coverage.

By thoroughly considering these factors, you can make an informed decision and select the ideal lithium-ion battery to optimize your forklift’s performance and maximize its operational efficiency.

Charging a Lithium-ion Forklift Battery

The onboard computer management system of a lithium forklift battery safeguards against overcharging. Image Source: Linde

Lithium-ion forklift batteries boast impressive charging efficiency. A full charge, from depletion (0%) to 100%, can be achieved in under 2 hours. Furthermore, the typical use cycle for these batteries is quite advantageous:

- 1-1.2 Hour Full Charge: The battery receives a full charge to prepare for operation.

- 8-Hour Runtime: The forklift operates at its peak for a full shift (approximately 8 hours).

- 1-2 Hour Opportunity Charging: During breaks or downtime, the battery receives a top-up charge to maintain optimal performance.

It’s important to note that Li-ion forklift batteries can be left on the charger indefinitely when not in use. The onboard computer management system safeguards against overcharging by automatically shutting down the charging process once the battery reaches full capacity. This eliminates the concern of the traditional battery memory effect and allows for flexible opportunity charging throughout the workday.

Lithium-Ion Forklift Battery Charging Essentials

Safe and Efficient Charging:

- Specialized Chargers: Lithium-ion forklift batteries require dedicated chargers with the correct power output. These chargers are surprisingly compact, often resembling a shoebox in size and weighing as little as 20 lbs. This allows for flexible placement near power outlets for maximum convenience. Wall-mounted or standalone options offer a small footprint and easy relocation when needed.

- Voltage Compatibility: Ensure the charger’s voltage range (12V, 24V, 36V, 48V, 72V, or 80V) matches your specific battery.

- Charging Parameters: Verify the charger is programmed to deliver the recommended Amp-hour (Ah) output based on your battery’s capacity and desired charging rate.

- Dual-Plug Batteries: Special charger models are needed for dual-plug batteries, enabling faster charging times (up to 50% reduction).

- Facility Power Supply: Ensure your facility’s electrical infrastructure can safely support the combined power demands of all charging forklifts.

Charger Maintenance:

Cable Inspection: Regularly check charger cables for damage or cracks in the insulation. Replace faulty cables immediately.

Lithium-Ion Battery Advantages:

- No Water Maintenance: Unlike lead-acid batteries, lithium-ion batteries do not require routine water level checks.

- Minimal Cleaning: Monthly cleaning is recommended to prevent chemical build-up that may corrode the battery tray and potentially void the warranty.

- No Post-Charge Cooling: Lithium-ion batteries don’t require a cooling-off period after charging.

Charging Process:

For quick top-ups during breaks (10-45 minutes) or shift changes, utilize opportunity charging. – Image Source: Linde

- Park the Forklift: Find a designated parking spot for the forklift.

- Safety First: Engage the parking brake, turn off the forklift, and don appropriate Personal Protective Equipment (PPE).

- Charger Off: Ensure the charger is switched off before connecting it to the forklift.

- Plug and Power On: Connect the charger to the forklift and activate the charger.

- Full Charge Duration: A full charge typically takes 1.5 to 2 hours.

- Opportunity Charging: For quick top-ups during breaks (10-45 minutes) or shift changes, utilize opportunity charging. This is not mandatory but can be scheduled based on your specific operational needs.

Smart Charging with BMS:

Lithium-ion forklift batteries are equipped with a Battery Management System (BMS) that regulates various parameters like amperage, voltage, and temperature during charging. Once connected, the BMS ensures safe and optimal charging for your battery.

Maintenance of Lithium-Ion Forklift Batteries:

While lithium-ion forklift batteries boast minimal maintenance needs compared to traditional lead-acid batteries, they still require some basic attention. Here’s a quick guide to keep your Li-ion batteries performing optimally:

- Storage Considerations: Avoid extended periods of inactivity, whether in the forklift or storage.

- Long-Term Storage (6+ Months): For Li-ion batteries left unused for over 6 months, check the charge level and either recharge or dispose of them following proper procedures.

- Monitor Charge Status: Develop a routine to regularly check your battery’s charge level.

- Manufacturer’s Instructions: Always adhere to the specific charging guidelines outlined in your Li-ion battery’s user manual provided by the manufacturer.

- Equalization Charging Not Required: Lithium-ion batteries do not require equalization charging, a process used with lead-acid batteries.

- Sealed Design: The sealed nature of Li-ion batteries eliminates the need for a dedicated watering system.

- Damaged Battery Precautions: Never attempt to recharge or use a damaged battery and avoid exposing batteries to excessive heat.

- End-of-Life Monitoring: As your Li-ion battery nears its lifespan, closely monitor its performance to avoid attempting to charge damaged units.

- Replacement Criteria: Consider replacing the battery if runtime dips below approximately 80% of its original capacity, or if charging times increase significantly.

- No User-Serviceable Parts: Lithium-ion batteries contain no user-serviceable parts. If you suspect a battery needs replacement, contact a reputable vendor like Ri-Go Lift for assistance.

Following these simple steps will ensure your lithium-ion forklift batteries provide reliable and long-lasting performance for your material handling operations.

Storage of Lithium-Ion Forklift Batteries

For extended storage periods exceeding 6 months, perform a top-up charge to around 50% capacity at least every 6 months. – Image Source: Linde

Maintaining proper storage conditions is crucial for maximizing the lifespan and safety of your lithium-ion forklift batteries. Here are key considerations:

Pre-Storage Preparation:

- Partial Charge: Never store batteries in a fully charged or completely discharged state. Instead, aim for a storage charge level of approximately 50%.

- Long-Term Storage (6+ Months): For extended storage periods exceeding 6 months, perform a top-up charge to around 50% capacity at least every 6 months.

Safe Storage Environment:

- Separate Storage: Always store the lithium-ion battery separately from the forklift for safety reasons.

- Temperature Control: Maintain a mild, dry storage environment with temperatures between 41°F and 68°F (5°C and 20°C). Avoid high temperatures.

- Protection from Elements: Store batteries away from direct sunlight, heat sources, and excessive humidity.

- Ventilation: Ensure the storage area is well-ventilated and dry with consistent temperature control.

- Terminal Protection: Prevent accidental contact between battery terminals during storage. Utilize terminal covers when available.

- Battery Segregation: Separate batteries by age and type to avoid terminal contact and maintain a clear distinction between newer and older batteries nearing their end of life.

Safety First:

Battery Storage Cabinet: For optimal safety, consider using a dedicated lithium-ion battery storage cabinet. These cabinets provide a controlled environment, insulation, and potential fire suppression capabilities to minimize the risk of thermal runaway events.

By following these storage best practices, you can ensure the longevity and safety of your lithium-ion forklift batteries, optimizing your investment and overall material handling operations.

8. Lithium Forklift Battery FAQ

Unlike lead-acid batteries that experience power loss as they discharge, lithium-ion batteries maintain consistent performance. – Image Source: Linde

Here is a list of frequently asked lithium-ion forklift battery questions. If you have further questions that are not addressed here, contact us.

How much do lithium-ion forklift batteries cost?

While upfront costs are a consideration, lithium-ion forklift batteries offer a compelling long-term value proposition. Individually, a lithium forklift battery typically ranges in price from $17,000 to $25,000. This represents a premium of 2 to 2.5 times the cost of comparable lead-acid batteries.

What is the biggest pro of switching to lithium-ion forklift batteries?

Lithium-ion forklift batteries offer a clear advantage over traditional lead-acid options. Their primary benefit lies in their ability to sustain power delivery, translating to significantly increased runtime and enhanced productivity. Unlike lead-acid batteries that experience power loss as they discharge, lithium-ion batteries maintain consistent performance. Furthermore, the ability to opportunity charge lithium-ion batteries during breaks or downtime minimizes downtime and maximizes operational efficiency.

But the benefits extend beyond mere runtime. Lithium-ion batteries offer a compelling long-term return on investment (ROI). Their increased efficiency translates to reduced electricity and labour costs, as fewer battery changes are required. Combined with improved productivity, this translates to significant cost savings over the lifespan of the battery.

What is the biggest con of switching to lithium-ion forklift batteries?

While lithium-ion batteries offer a compelling value proposition in the long run, their biggest hurdle is the initial cost. Individually, a lithium-ion forklift battery can range from $17,000 to $25,000, depending on the manufacturer and specific application. This significant upfront investment may not be financially justifiable for smaller operations with less demanding usage patterns. Therefore, carefully evaluating your budget and operational needs is crucial before making the switch to lithium-ion technology.

Are many operations switching to Lithium batteries?

The landscape of electric forklifts is shifting towards lithium-ion batteries. Operations with demanding schedules, like multi-shift environments in food processing, manufacturing, and 24/7 material handling, see the most significant benefits. Even cold storage operations find lithium-ion batteries advantageous due to their ability to fast-charge in freezing temperatures (including freezers) and maintain optimal capacity in cold environments.

While the initial cost of lithium batteries may seem higher, significant long-term savings are achievable:

- Extended Lifespan: Lithium-ion batteries boast a lifespan of 2 to 4 times longer than lead-acid batteries.

- Reduced Energy Costs: They deliver 30% greater energy efficiency and charge up to 8 times faster than their lead-acid counterparts.

- Minimized Downtime: Opportunity charging during breaks eliminates the need for battery swaps, maximizing runtime and reducing downtime.

- Lower Labor Costs: Lithium-ion batteries require minimal maintenance, eliminating tasks like watering and equalizing.

- Enhanced Productivity: Longer runtimes translate directly to improved operational efficiency and productivity.

- Space Optimization: Reduced reliance on dedicated charging areas frees up valuable real estate for storage or other uses.

By switching to lithium-ion batteries, you can unlock a multitude of benefits that contribute to a lower total cost of ownership and a more efficient material handling operation.

How long does it take to charge a lithium-ion forklift battery?

Lithium-ion forklift batteries offer exceptional charging flexibility compared to traditional lead-acid batteries. Here’s a breakdown of their charging times:

- Fast Charging: Up to 80% charge can be achieved in as little as one hour.

- Opportunity Charging: Throughout the day, short top-up charges of 15-30 minutes can be utilized.

- Full Charge: A complete charge typically takes 1 to 2 hours.

In contrast, lead-acid batteries require a lengthy 8-hour charge followed by an additional 8-hour cooling period, significantly impacting operational efficiency. This highlights a key advantage of lithium-ion technology for forklift applications.

What is the ideal operating temperature range for a lithium-ion forklift battery?

Lithium forklift batteries can operate in a wide range of temperatures.

Lithium-ion forklift batteries boast a wide operating temperature range, typically spanning from -4°F to 130°F (-20°C to 54°C). However, for optimal performance and battery health, it’s recommended to operate them within a narrower range of 50°F to 110°F (10°C to 43°C).

Maintaining this ideal temperature range offers several benefits:

- Preserve Peak Performance: The battery delivers its maximum power and efficiency when operated within this range.

- Maximizes Lifespan: Extreme hot or cold conditions can accelerate battery degradation, reducing the number of charge cycles it can endure. Lithium-ion batteries operated within the optimal range can achieve up to 6,000 cycles.

Can a lithium-ion forklift battery be overcharged?

While technically possible, overcharging a lithium-ion forklift battery is unlikely under normal operating conditions. These batteries typically reach a full charge within 1 to 2 hours. They are equipped with a Battery Management System (BMS) that acts as a safeguard. The BMS constantly monitors the charging process and automatically shuts down the charger once the battery reaches full capacity, preventing overcharging. This offers peace of mind and allows for safe, convenient charging practices.

Can I completely discharge (over-discharge) a lithium-ion forklift battery?

Lithium-ion forklift batteries typically have a higher depth of discharge (DoD) compared to lead-acid batteries, ranging from 80% to 100%. While it’s not ideal to completely deplete the battery, occasional deep discharges are less detrimental to lithium-ion than lead-acid technology.

However, it’s still recommended to avoid habitual over-discharging. This can cause unbalanced cell discharge within the battery, potentially leading to permanent damage and reduced lifespan.

For optimal battery health, practicing regular charging and avoiding complete depletion is recommended.

Can I leave a lithium-ion forklift battery on the charger indefinitely?

Yes, you can safely leave a lithium-ion forklift battery on the charger even when not in use. Unlike lead-acid batteries, lithium-ion batteries are equipped with a Battery Management System (BMS). This onboard computer system monitors the charging process and automatically shuts down once the battery reaches full capacity, preventing overcharging. This eliminates the concern of battery memory effect and allows for flexible opportunity charging throughout the workday.

Do lithium-ion forklift batteries degrade over time?

Yes, lithium-ion forklift batteries, like most batteries, do experience degradation over time. This is measured in charging cycles and manifests as a gradual reduction in the battery’s capacity to hold a charge. The typical lifespan for a lithium-ion forklift battery ranges from 2,000 to 3,000 charging cycles, with some high-quality models reaching up to 6,000 cycles.

This degradation is an irreversible process, meaning the battery’s capacity won’t recover. As a result, you may notice a decrease in runtime as the battery ages. However, compared to lead-acid batteries, lithium-ion batteries offer a significantly longer lifespan and maintain a higher percentage of their capacity throughout their life cycle.

How can I maximize the lifespan of my lithium-ion forklift battery?

Regularly inspect the battery casing for cracks or leaks.

Here are some key strategies to extend the life of your lithium-ion forklift battery and ensure optimal performance:

- Temperature Control: Both extreme heat and cold can be detrimental. Avoid exposing the battery to high temperatures during operation or storage. Similarly, minimize charging the battery in very cold environments.

- Proper Charging Practices: Always use the designated charger for your specific lithium-ion forklift battery. Following the manufacturer’s recommended charging procedures is crucial to avoid stressing the battery.

- Preventative Maintenance: Refrain from physically tampering with the battery or its components. Any damage can compromise safety and performance. Regularly inspect the battery casing for cracks or leaks, and report any concerns to a qualified technician.

By implementing these practices, you can promote the longevity of your lithium-ion forklift battery and ensure it delivers reliable service for years to come.

What factors can shorten the lifespan of a lithium-ion forklift battery?

While lithium-ion batteries naturally degrade over time, certain factors can accelerate this process and potentially lead to premature failure. Here are some key culprits:

- Extreme Temperatures: Both excessively high and low temperatures can be detrimental to lithium-ion batteries. Heat exposure can damage the battery cells, while cold temperatures can significantly reduce capacity and hinder charging efficiency. Always operate and store your lithium-ion forklift battery within the recommended temperature range for optimal performance and lifespan.

- Deep Discharging: Although lithium-ion batteries are more tolerant of occasional deep discharges compared to lead-acid batteries, habitually depleting the battery completely can stress the cells and accelerate degradation.

- Improper Charging Practices: Using incompatible chargers or failing to follow the manufacturer’s recommended charging procedures can put undue stress on the battery and shorten its lifespan.

By following best practices for charging, operation, and storage, you can significantly extend the lifespan of your lithium-ion forklift battery and maximize your return on investment.

Can a lithium-ion forklift battery last 20 years?

The potential lifespan of a lithium-ion forklift battery is estimated to be around 10-15 years, with some manufacturers even suggesting a possibility of reaching 20 years. However, it’s important to consider a few factors:

- Limited Long-Term Data: Lithium-ion technology is still relatively new in the industrial forklift market compared to lead-acid batteries. Therefore, extensive real-world data on their long-term performance beyond 10 years is limited.

- Usage Patterns: The actual lifespan of a lithium-ion forklift battery can be significantly influenced by usage patterns and operating conditions. Factors like depth of discharge, temperature extremes, and charging frequency can all impact battery health.

While reaching 20 years may be possible under ideal circumstances, it’s essential to focus on maximizing battery life through proper charging practices and operating within the recommended temperature range. By following these guidelines, you can expect a lithium-ion forklift battery to deliver reliable performance for a decade or more.

9. Summary

Total Cost of Ownership Comparison

While the upfront cost of lithium-ion batteries may seem higher initially, the long-term benefits and ROI are certainly worth the investment – Image Source: Hangcha

The transition from lead-acid to lithium-ion forklift batteries represents a significant advancement in intralogistics. This comprehensive guide has equipped you with the knowledge to make informed decisions for your material handling operation. We’ve explored the technical aspects, delved into the advantages and considerations, and even provided guidance on compatibility and implementation.

While the upfront cost of lithium-ion batteries may seem higher initially, the long-term benefits are undeniable. From increased productivity and reduced downtime to lower maintenance needs and energy savings, lithium-ion technology offers a compelling return on investment.

Ultimately, the decision to switch to lithium-ion depends on your specific needs and budget. By carefully weighing the factors outlined in this guide, you can determine if lithium-ion is the right choice to power your future and elevate your forklift operations to new levels of efficiency and performance.

If you have further questions or would like assistance in choosing the right forklift battery for your operations, contact us.

Looking for a Lithium Forklift Dealer You Can Rely On? Contact Ri-Go Lift

Since 1977, Ri-Go Lift Truck has been serving customers in Ontario and Quebec with everything they need for material handling. We are committed to providing you with quality service and a high level of customer satisfaction.

We are your authorized dealer for the following top brands:

- Linde Lift Trucks, Power Pallet Trucks, Tow Tractors and Stackers

- Hangcha Forklifts Full Lineup of Electric & IC Equipment

- Blue Giant Lift Trucks and Pallet Movers

- Komatsu Forklifts and Reach Trucks

- Mariotti Lift Trucks – The Worlds Smallest Lift Truck

- Baoli Lift Trucks

- Advance Sweepers and Scrubbers

- Skyjack Genie Booms and Scissor Lifts

In addition to our authorized distributorships, we can also provide you with:

- Large selection of used forklifts

- Operator Training Department – open 7 days a week

- Parts Departments – over 1.4 million dollars of parts on hand for all makes and models

- Service Department – highly trained technicians

- Leasing and Rentals

No matter what your material handling needs are, we can help. Contact us today to let us know how we can be of service.

What Our Customers Think…

“I’ve been using RIGO Lift for the last 3-4 years now for my equipment rental needs. They have a fantastic crew working together and they are VERY efficient and reliable as a whole. Whenever I need electric equipment which is hard to come by, I know they are always able to provide. Their equipment is rare to breakdown because they provide machinery that is well kept and in good condition. I definitely recommend you reach out to Steve and the team because you will not be disappointed!”

– Heloise Vieira