Electric forklifts are steadily becoming the first choice of businesses over traditional internal combustion engine forklifts and for some very good reasons. Click on the following sections to learn more about the great advantages of purchasing an electric forklift and what to look for when you are buying one.

- Advantages of Purchasing Electric Forklifts

- Lithium-Ion vs Lead-Acid Batteries

- What to Look for When Buying Electric Forklifts

If you are looking for a new internal combustion OR Electric forklift and want the best selection and best service possible, contact us.

Electric Forklifts

1. Advantages of Purchasing Electric Forklifts

Electric forklifts have many great advantages over IC forklifts.

Electric forklifts offer several advantages over internal combustion (IC) forklifts, making them an increasingly popular choice for businesses. Here are the key advantages of buying electric forklifts:

Environmentally friendly:

Electric forklifts produce zero tailpipe emissions at the point of use, as they do not burn fossil fuels like IC forklifts. By switching to electric, you can significantly reduce your carbon footprint and contribute to a cleaner environment for both your employees’ benefit and the worlds’.

Cost savings:

Electric forklifts have lower operating costs compared to IC forklifts. Electricity is generally cheaper than gasoline, LPG or diesel fuel, resulting in lower energy costs per hour of operation. Additionally, electric forklifts require less maintenance as they have fewer moving parts. Given this, they do not require any engine oil changes or filter replacements.

Our IC Calculator can show you how much your specific operation can save with an Electric forklift vs an IC one – call us and we can send you one or help you complete one to see the exact savings! Contact us at sales@rigolift.com or 416-213-7277 and ask for sales.

Although electric forklifts may have a higher upfront cost compared to IC forklifts, their long-term cost savings, including lower fuel costs and reduced maintenance requirements, can dramatically outweigh the initial investment.

Noise reduction:

Electric forklifts operate much more quieter than their IC counterparts. This is especially advantageous in indoor environments, where noise pollution can be a concern. Quieter operation enhances workplace comfort, reduces noise-related fatigue, and allows for better communication among workers.

Improved indoor air quality:

Using electric forklifts will improve the air quality in your facility.

Since electric forklifts do not emit exhaust fumes, they contribute to better indoor air quality. This is especially important in warehouses or facilities with limited ventilation. Electric forklifts help create a healthier work environment by eliminating harmful emissions such as carbon monoxide and other particulate matter.

Enhanced maneuverability:

Electric forklifts offer smoother acceleration, deceleration, and maneuverability compared to IC forklifts. Batteries allowed the development of Power Pallet trucks, 3 wheel Counterbalanced and Reach Trucks that can operate in very narrow aisles and are not available in Internal Combustion Power.

Electric motors provide instant torque, resulting in quicker response times and more precise control. This can be particularly beneficial in tight spaces or narrow aisles, improving overall operational efficiency and safety.

Operator comfort and safety:

Electric forklifts are known for their ergonomic design and reduced vibration levels. This helps minimize operator fatigue and discomfort, leading to improved productivity and reduced risk of musculoskeletal injuries.

Electric forklifts also eliminate the risk of fuel spills or leaks, reducing the potential for accidents and ensuring a safer work environment.

2. Lithium-Ion vs Lead-Acid Batteries

Electric forklifts have always been powered with Lead acid batteries that require watering weekly and maintenance in order to ensure they last as long as possible. Until recently this was a downfall of electric forklifts – but now there is an alternative.

Lithium-ion (Li-ion) batteries have become a superior alternative to lead-acid batteries for forklifts. Here are the key reasons why lithium-ion batteries are considered better for forklift applications:

Fast charging:

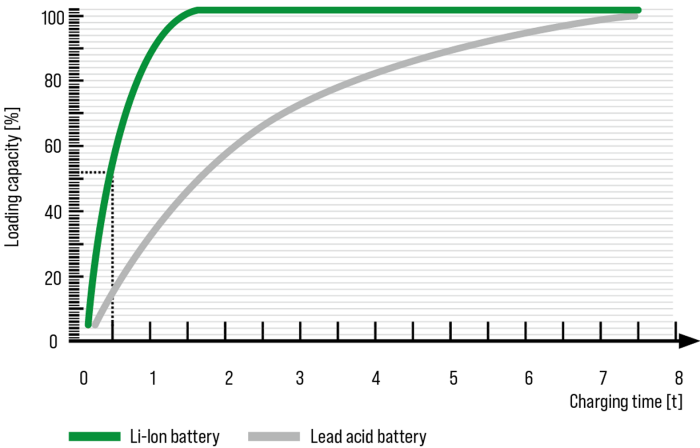

Image source: Hangcha

Li-ion batteries offer much faster charging times compared to lead-acid batteries. As you can see from the green line on the above graph, Li-ion batteries can be charged up to 50% in as little as 30 minutes and can be fully charged in as little as 2 hours. *

The grey line on the graph shows the more traditional lead-acid battery charge curve and it is a much more gradual curve. This shows that lead-acid batteries take longer to fully charge, typically several hours.

The faster charging capabilities and reduced time spent recharging mean that lithium-ion forklifts are ready to go when they are needed. Many customers can get 20-22 operating hours per day with an efficient electric forklift such as a Linde 1252 or 346 series forklift and a quality Lithium Battery and Fast Charger. No more changing batteries! No more watering batteries!

Longer lifespan:

Lithium-ion batteries also have a significantly longer lifespan compared to lead-acid batteries. While lead-acid batteries typically last 1,500 to 2,000 charge cycles, Li-ion batteries can endure 3,000 to 5,000 charge cycles or more.

This extended lifespan reduces the need for frequent battery replacements, resulting in cost savings over time. Often Lead acid batteries will have a 3-5 year warranty whereas the equivalent Lithium battery can have double that warranty.

Higher energy density resulting in smaller size:

Li-ion batteries have a higher energy density, meaning they can store more energy in a smaller and lighter package. This allows forklifts to carry larger battery capacities without sacrificing valuable workspace or load capacity. The higher energy density also translates into longer runtimes between charges, boosting productivity and reducing downtime.

In addition, the smaller footprint of lithium batteries means that there is more space for other components, such as additional counterweights or attachments, without compromising load capacity. The compact size of Li-ion batteries also facilitates easier installation and removal, reducing downtime during battery replacement.

Maintenance-free operation:

Li-ion batteries are virtually maintenance-free compared to lead-acid batteries. Lead-acid batteries require regular watering, equalizing charges, and cleaning of acid spills. In contrast, Li-ion batteries eliminate the need for such maintenance tasks, saving time, effort, and costs associated with battery upkeep.

Opportunity charging:

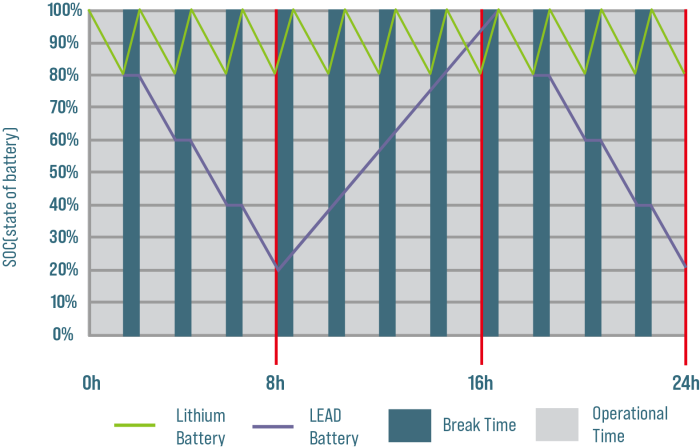

Image source: Hangcha

Unlike lead-acid batteries, Li-ion batteries do not experience the “memory effect.” This means they can be recharged at any time without requiring a complete discharge first. This type of continuous charging is called “opportunity charging.” With opportunity charging, forklifts can be charged during short breaks or downtime, ensuring continuous operation and maximizing productivity.

The green line in the above graph depicts how opportunity charging works. At every break during the day, your forklift can be recharged even though it hasn’t fully depleted its charge. This means your truck can be in use for consecutive shifts during the day.

The purple line shows you that a lead-acid battery traditionally needs to be fully discharged in order to be charged again. The charging and cooling process can take 8 hours or more so during that charging time, your forklift cannot be used.

(Note – with some special Opportunity Chargers with modules on lead acid batteries, you can also Opportunity charge safely and get up to 18-19 hours of operation per day but regular care/battery maintenance and watering is still required).

Sealed:

The cells in li-ion batteries are individually sealed which means that they are less likely to leak than a lead-acid battery is. This makes them more environmentally friendly. The sealing process also means that they can be operated in any position: on their side, upside down, or standing up. They can also operate in wet environments, indoors and outdoors and in cold or hot environments with the right specification.

Intelligent battery management:

Li-ion batteries come equipped with advanced battery management systems (BMS) that monitor and regulate battery performance. BMS ensures optimal charging and discharging, prevents overcharging or over-discharging, and provides real-time data on battery status. This enables better battery utilization, enhances safety, and allows for more efficient fleet management.

3. What to Look for When Buying Electric Forklifts

IPX water rating:

Check that your forklift can be used around water.

If you want to use your forklift outside or in a facility where there are frequent washdowns such as in food production plants, then make sure you choose an electric forklift that can get wet. Look for electric forklifts with an IPX4 water resistance rating. This rating makes it suitable for outdoor operation or in wet environments.

Cold area application:

If you want to use your electric forklift outside or in cold area applications, make sure that it is designed for those situations. For example, Hangcha’s lithium-ion forklifts have an electrical heating element that makes them suitable to run in cold applications.

Their lithium-ion batteries can heat up to 32 degrees F in one-third of the time that it would take a lead-acid battery truck to heat up to this temperature. As a result, Hangcha lithium-ion forklifts can keep a high level of performance in temperatures that are below freezing.

Temperature monitors and safety protocols prevent the battery from reaching unsafe temperatures and will stop the charger if anything appears outside the normal range.

Reputable brand that specializes in lithium-ion technology:

When purchasing a lithium-ion forklift, look for a brand that specializes in lithium-ion technology and has a complete line-up of lithium-ion forklifts to choose from. It is also a good idea to go to a reputable forklift dealer that has been in the business for a long time in order to get all of your questions answered and to get knowledgeable help in selecting the perfect forklift for your needs.

At Ri-Go Lift we support Linde and Hangcha Forklifts as well as CATL Lithium Batteries because they are proven and well built. Let us know how we can help you answer all your Forklift related questions. 416-213-7277 or sales@rigolift.com.

Great warranty and high quality:

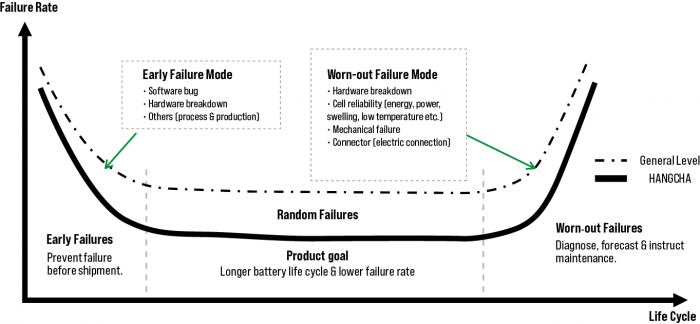

Image source: Hangcha

Make sure that you check the type of warranty you are getting. For example, Hangcha Group offers up to a 10-year or 20,000 hours warranty on their CATL Lithium Iron Phosphate (LiPO4) battery packs. These battery packs will also retain at least 80% residual capacity over 4,000 full charges.

In addition, the lithium-ion batteries designed by Hangzhou Pengcheng New Energy Technology Co, Ltd. and used in Hangcha’s electric forklifts are considerably less prone to failures when compared to the average amount of failures a lithium-ion battery has over its life cycle.

The above chart compares the general failure rate of lithium-ion batteries to that of Hangcha lithium-ion batteries. As you can see the Hangcha batteries have a consistently lower failure rate.

Trust Ri-Go Lift for Your Linde and Hangcha Electric Forklifts

Since 1977, Ri-Go Lift Truck has been serving our customers in Ontario and Quebec with everything they need for material handling. We are committed to providing you with quality service and a high level of customer satisfaction.

We are your authorized dealer for the following top brands:

- Linde Lift Trucks, Power Pallet Trucks, Tow Tractors and Stackers

- Blue Giant Lift Trucks and Pallet Movers

- Komatsu Forklifts and Reach Trucks

- Mariotti Lift Trucks – The Worlds Smallest Lift Truck

- Baoli Lift Trucks

- Advance Sweepers and Scrubbers

- Skyjack and Genie Booms and Scissor Lifts

We are also proud to offer you the full lineup of Hangcha forklifts!

In addition to our authorized distributorships, we can also provide you with:

- Large selection of used forklifts

- Operator Training Department – open 7 days a week

- Parts Departments – over $1.4 million dollars of parts on hand for all makes and models

- Service Department – highly trained technicians

- Leasing and Rentals

No matter what your material handling needs are, we can help. Contact us today to let us know how we can be of service.

What Our Customers Are Saying…

“Great company with an awesome team. The general manager, Steve, always go above and beyond!” -Amanda Araujo