How long do forklifts last? The answer to this question is essential for businesses wanting to optimize productivity and avoid unexpected expenses. In this guide, we’ll take a look at the factors that impact a forklift’s longevity and share practical advice on extending its lifespan to ensure reliable performance for years to come. Click on each section to learn more:

- How Long Do Forklifts Last?

- Understanding Forklift Hours

- Factors that Affect How Long Forklifts Last

- Forklift Economic Life vs Forklift Useful Life

- How Long Do Forklifts Last? Electric vs IC

- Is it Time to Replace Your Forklift? How to Know

- How to Extend Your Forklift’s Lifespan

- Forklift Disposal Options

- The Linde Advantage: Why Linde Forklifts Last Longer

By understanding the factors that affect how long your forklift will last, following recommended manufacturer preventative maintenance strategies, and making informed replacement decisions, you can maximize your return on investment while keeping your material handling processes running smoothly. Reach out to Ri-Go Lift today to discuss your forklift requirements and discover how our expertise can help you achieve peak performance and value from your forklift fleet.

How Long Do Forklifts Last? Quick Overview

How long do forklifts last? around 10,000 hours, though this can vary based on different factors.

If you want a quick summary of the answer to the question “How long do forklifts last”, read the following. For a more in-depth answer, keep reading below.

- Average Lifespan: Forklifts typically last around 10,000 hours, though this can vary based on factors like usage intensity, operating environment, operator behaviour, fuel type, maintenance practices, and brand reliability.

- Usage Measurement: Unlike vehicles measured in miles, forklift usage is tracked in hours. A general rule is that 200 forklift hours equate to approximately 3,000 car miles.

- Useful Life vs. Economic Life: ‘Useful life’ refers to the total operational lifespan of a forklift, while ‘economic life’ denotes the point at which maintenance costs outweigh the benefits of continued use. It’s advisable to consider replacing a forklift when maintenance expenses reach about $4 per hour (for electric forklifts and smaller internal combustion forklifts).

- Replacement Options: When retiring a forklift, options include selling it, recycling it at a scrap yard, repurposing it for spare parts, or trading it in at an equipment dealership.

Regular maintenance and mindful operation are emphasized as crucial for extending a forklift’s lifespan and ensuring cost-effective performance.

1. How Long Do Forklifts Last?

How long do forklifts last? The answer isn’t one-size-fits-all. A forklift’s lifespan depends on various factors, but a key concept to understand is Forklift Useful Life—the period during which the forklift operates efficiently, safely, and cost-effectively within your operation’s demands.

Average Lifespan of a Forklift

Manufacturers generally estimate a forklift’s lifespan at around 10,000 hours of operation, but real-world conditions such as usage intensity, maintenance, and operating environment can significantly influence this number. Proper maintenance and attention can extend this lifespan, making your forklift a valuable asset for even longer.

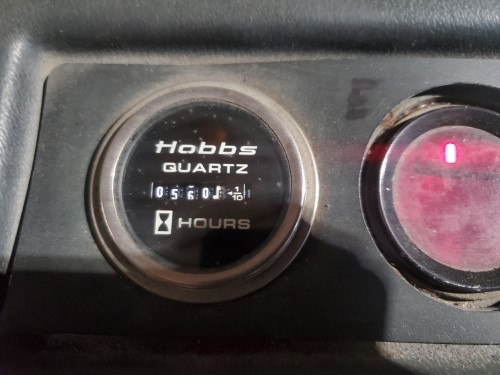

Reading Your Forklift’s Hour Meter

Understanding how many hours your forklift has logged is crucial to gauging its remaining useful life. Most forklifts come with an hour meter that tracks engine runtime. Here are the two types you might encounter:

Digital Hour Meters

Digital hour meters are found in more modern forklifts.

Common in modern forklifts, these meters display the total runtime in a clear digital format, often on an LCD screen. They may show readings as whole hours (e.g., 1254 hours) or in fractions (e.g., 1254.5 hours).

Analog Hour Meters

Analog hour meters look like an odometer.

Found on older models, these resemble a car odometer with rotating dials that count whole hours. They can be less precise than digital meters and may lack the ability to show tenths of hours.

Locating the Hour Meter

The hour meter is typically located on the forklift’s instrument panel, either directly in front of the operator or on a side panel near the steering wheel. If you’re unsure of its location, consult your forklift’s owner’s manual for guidance.

Important Notes on Hour Meters

Older analog hour meters may reset to zero after reaching their maximum reading (e.g., 9999 hours), potentially leading to inaccurate assessments of total usage if maintenance records are unavailable. To avoid confusion, always check the forklift’s service records or consult the previous owner for a more complete history.

By accurately tracking usage hours and understanding your forklift’s operational limits, you’ll gain insight into its remaining lifespan. Next, we’ll discuss the factors that impact forklift useful life and how proper care and maintenance can help you get the most out of your investment.

2. Understanding Forklift Hours

How long do forklifts last? Regular maintenance can help to extend its lifespan.

When evaluating a forklift’s condition and lifespan, understanding its logged hours is essential. Forklift hours give you a snapshot of its usage, but their significance depends on various factors such as maintenance, type, and brand. Here’s what you need to know about forklift hours and how they influence a forklift’s value and reliability.

What are Low and High Hours?

Low Hours:

Forklifts with fewer than 5,000 hours are generally considered to have low usage. These are typically newer models with minimal wear and tear, offering extended service life if maintained properly.

High Hours:

Forklifts with more than 10,000 hours are often categorized as high usage. However, the implications of high hours depend on the brand, model, and maintenance history. High-hour forklifts may require more frequent repairs and servicing.

Factors to Consider When Assessing Forklift Hours

Forklift Type:

Electric forklifts tend to have a longer lifespan compared to internal combustion (IC) forklifts. Higher hours might be acceptable for an electric forklift, especially if it uses a lithium battery, which typically lasts longer than lead-acid batteries. However, factors such as charging cycles and the number of shifts per day also affect their lifespan.

Maintenance History:

A well-maintained forklift can outlast its peers with lower hours but poor upkeep. Regular maintenance, including timely repairs and part replacements, plays a critical role in extending a forklift’s useful life, regardless of its total hours.

Brand and Model:

Some forklift brands last longer than others.

Some forklift brands are renowned for their durability and performance over time. Researching a specific brand and model or consulting with a forklift specialist can provide valuable insights into its expected lifespan.

General Hour Guidelines

Here’s a breakdown of what different hour ranges typically mean for a forklift’s condition:

Under 2,000 Hours:

Ideal for a near-new forklift with minimal wear and tear.

2,000–5,000 Hours:

Considered a low range for a well-maintained forklift and likely to offer years of reliable service.

5,000–10,000 Hours:

This is an average range for forklifts. The condition at this stage heavily depends on the quality of maintenance.

10,000–15,000 Hours:

A high range for IC forklifts, often nearing the end of their economic life. For electric forklifts, this range can still be acceptable if they’ve been well-maintained.

Over 15,000 Hours:

Very high usage for most forklifts, often signaling the end of their useful life regardless of type.

The Linde Difference: Linde forklifts are generally German built and very different than other forklift brands. Linde forklifts are often Hydrostatic drive and are built to last 20,000 hours! – literally twice as long as other brands! Better materials, better design and manufacturing allows Linde to outlast other brands.

Beyond the Numbers

Hours are just one part of the equation when evaluating a forklift. Always inspect the forklift thoroughly, review its maintenance records, and consider the reputation of its brand and model.

At Ri-Go Lift Truck, we can help you analyze your fleet, assess the condition of your forklifts, and develop a plan to keep them in peak operating condition. Call us today at 416-213-7277 to discuss how we can support your material handling needs.

3. Factors that Affect How Long Forklifts Last

Match the forklift’s features to the specific demands of your operation.

Just like an athlete relies on training and habits to perform at their best, a forklift’s longevity depends on multiple factors. Here’s a breakdown of the key influences on a forklift’s useful life, along with actionable tips to maximize its performance and extend its lifespan.

Maintenance Practices

Regular and thorough maintenance is the cornerstone of extending a forklift’s useful life. By adhering to the manufacturer’s maintenance schedule, you can address minor issues before they escalate into costly repairs.

How to Extend Lifespan:

- Daily Inspections: Conduct pre-shift checks to identify leaks, loose parts, or visible damage.

- Scheduled Maintenance: Follow the manufacturer’s recommended intervals for comprehensive inspections by qualified technicians.

- Lubrication: Properly lubricate all moving parts as per the manufacturer’s guidelines to reduce friction and wear.

- Proactive Repairs: Replace worn filters, fluids, and components before they fail to prevent larger issues.

Application and Environment

The tasks a forklift performs and the conditions it operates in play a significant role in its wear and tear. Harsh environments with extreme temperatures, high humidity, dust, or corrosive materials can accelerate component degradation.

How to Extend Lifespan:

- Match the forklift’s features to the specific demands of your operation (e.g., using sealed cabins and advanced filtration in dusty environments).

- Operate forklifts in controlled environments whenever possible to limit exposure to extreme elements.

Operator Behavior

How a forklift is driven directly affects its lifespan. Rough operations, such as harsh braking, rapid acceleration, or overloading, can strain the drivetrain, tires, and lifting mechanisms.

How to Extend Lifespan:

- Training Programs: Provide comprehensive training to operators, focusing on safe and efficient driving practices.

- Smooth Operation: Encourage gentle starts, stops, and turns to reduce stress on mechanical components.

- Capacity Awareness: Emphasize the importance of not exceeding the forklift’s rated capacity and update capacity plates if attachments change.

- Pre-shift Inspections: Require operators to perform quick checks before each shift to identify potential issues early.

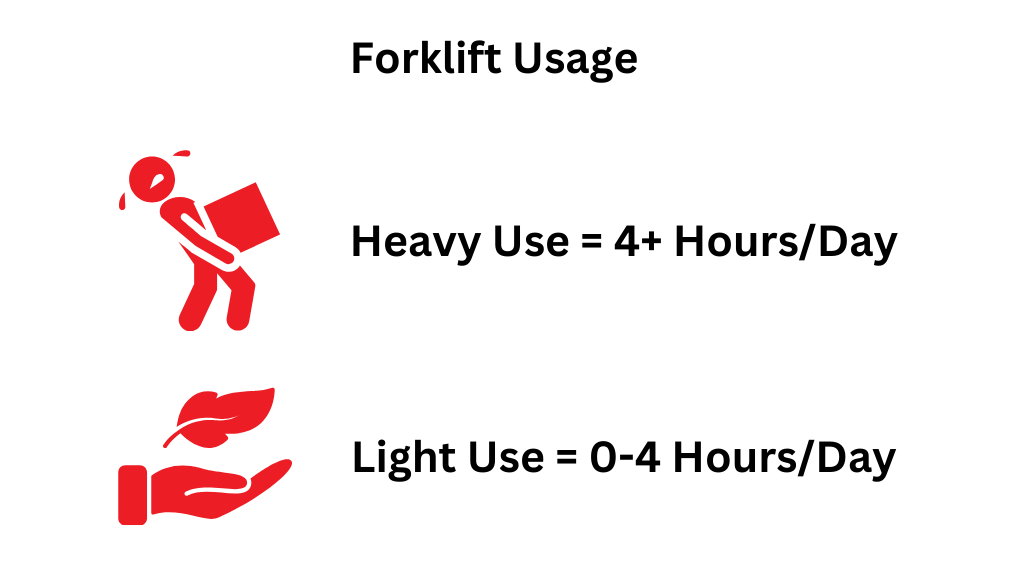

Hours of Operation

Forklift usage is typically measured in hours. Higher operating hours lead to increased wear and tear on components. Heavy use forklifts, those used for 4 hours or more each day, will tend to wear out faster than light use forklifts, those used from zero to 4 hours each day.

How to Extend Lifespan:

- Implement a strategic scheduling system to distribute workload evenly across your fleet.

- Prioritize preventive maintenance for forklifts with higher hours to minimize downtime and extend usability.

Fuel Type and Quality

The type of fuel used (electric, gas, propane) and its quality can significantly affect engine performance and longevity. Poor-quality fuel can cause incomplete combustion, engine deposits, and reduced efficiency.

How to Extend Lifespan:

- Always use the fuel type and quality recommended by the manufacturer for your forklift model.

- Perform regular fuel system maintenance, including filter replacements, to ensure clean and efficient fuel delivery.

Brand and Model Durability

Not all forklifts are created equal. Some brands and models are known for their exceptional durability and performance over time.

How to Extend Lifespan:

- Research the reputation of the forklift’s manufacturer and specific model.

- Consult with a forklift specialist to choose equipment designed for long-term reliability in your operation.

By understanding these key factors and adopting proactive practices, you can significantly extend your forklift’s lifespan, reduce downtime, and maximize your return on investment.

4. Forklift Economic Life vs Forklift Useful Life

There comes a point at which maintaining and operating an older forklift becomes more expensive than replacing it with a new one.

Understanding the difference between a forklift’s useful life and its economic life is key to managing your fleet effectively and controlling costs. While useful life refers to the total operational lifespan of a forklift, economic life focuses on the financially sensible period to keep the forklift in service.

What is Forklift Economic Life?

Forklift economic life is the point at which maintaining and operating an older forklift becomes more expensive than replacing it with a new one. It’s not just about whether the forklift can still run; it’s about whether it makes financial sense to keep it running.

Why the Distinction Matters

Cost Management

Focusing solely on a forklift’s useful life can lead to rising maintenance expenses as the machine ages. Older forklifts often require frequent repairs, which can outweigh the benefits of keeping them in operation. Understanding the economic life helps businesses avoid unnecessary costs and maintain a balanced budget.

Enhanced Safety

As forklifts age, their components wear down, increasing the risk of safety hazards for operators and surrounding workers. Replacing a forklift before it exceeds its economic life ensures that safety standards remain high and accidents are minimized.

Boosted Productivity

Modern forklifts often come equipped with advanced features and improved technology that enhance efficiency and reduce downtime. Holding on to an outdated forklift beyond its economic life can limit productivity and slow down operations, impacting your bottom line.

Minimized Downtime

Forklifts past their economic life are more prone to breakdowns, causing unexpected disruptions. Regularly evaluating your fleet’s economic life helps you transition to newer models that deliver reliability and keep operations running smoothly.

Making Informed Decisions

Knowing when a forklift has reached the end of its economic life empowers you to make smarter fleet management decisions. Tools such as economic life calculators provided by manufacturers or preventative maintenance agreements can help determine the ideal time for replacement. These resources ensure you’re maximizing your investment while keeping your fleet in optimal condition.

By balancing useful life and economic life, you can achieve a fleet that is both cost-effective and high-performing, contributing to smoother operations and long-term success.

5. How Long Do Forklifts Last? Electric vs IC

Lithium-Ion electric forklifts are economical and environmentally friendly.

When considering the lifespan of a forklift, the power source plays a significant role. Forklifts are powered either by internal combustion (IC) engines, fueled by gas, propane, or diesel, or by electric motors powered by batteries. Both types have their strengths and weaknesses, and understanding these can help you choose the best fit for your operation.

Electric Forklifts: Long Lifespan with Lower Maintenance

Electric forklifts are known for their longer useful life, thanks to their simpler design and cleaner operation.

Advantages:

- Fewer Moving Parts: The electric drivetrain has fewer components compared to IC engines, reducing wear and the need for major repairs.

- Cleaner Operation: Electric forklifts don’t produce combustion byproducts, minimizing engine wear and maintaining cleaner internal systems.

- Lower Stress Levels: Smooth acceleration and lower operating temperatures reduce strain on the drivetrain, extending the machine’s life.

Challenges:

- Battery Life: Forklift batteries degrade over time, losing capacity and requiring replacement. Heavy usage or multi-shift operations can accelerate this process.

- Charging Downtime: Electric forklifts need recharging, which can impact productivity in high-demand operations. However, lithium-ion batteries mitigate this with faster charging and the ability for opportunity charging during breaks.

IC Forklifts: Power and Performance at a Cost

The H20 – 35 diesel and gas forklift trucks from Linde are the most efficient counterbalanced forklift trucks in their performance class..

Internal combustion forklifts excel in specific applications, offering strength and convenience, but often have a shorter lifespan compared to electric models.

Advantages:

- Quick Refueling: Refueling IC forklifts is faster than recharging electric models, making them ideal for fast-paced operations with minimal downtime.

- High Power Output: IC engines deliver more raw power, making them suitable for heavy-duty tasks. Modern electric models, especially those with lithium-ion batteries, are beginning to close this gap.

Challenges:

- Complexity: IC engines have more moving parts, increasing the likelihood of wear and tear and requiring more frequent repairs.

- Environmental Factors: Combustion generates heat and byproducts, which can accelerate component wear over time.

Making the Right Choice

The longer useful life of electric forklifts often makes them a better investment for operations prioritizing low maintenance and cleaner performance. However, IC forklifts remain essential for certain high-power applications or in environments where refuelling speed is crucial.

Key Considerations:

- For multi-shift operations with heavy use, lithium-ion-powered electric forklifts are a reliable option.

- Choose IC forklifts if immediate refuelling or high power is critical to your operations.

- Evaluate your operating environment, load requirements, and downtime tolerance to determine the most suitable option.

By carefully assessing these factors, you can select the forklift type that offers the best balance of lifespan, performance, and cost-efficiency for your needs.

6. Is it Time to Replace Your Forklift? How to Know

If your forklift is struggling to handle loads it once managed with ease, it may be time to get a new one.

Recognizing when a forklift has reached the end of its economically viable lifespan is essential to maintaining efficiency, safety, and cost-effectiveness in your operation. Here are the key signs that it might be time to replace your forklift:

Rising Repair Costs

One of the clearest indicators is a noticeable increase in repair frequency and associated costs. As forklifts age, their components wear down, and repairs become more frequent and expensive. When these maintenance expenses outweigh the benefits of keeping the forklift in service, it’s time to consider a replacement.

Decline in Performance

Aging forklifts often show a drop in performance, which can affect your operations in several ways:

- Reduced Lifting Capacity: Struggling to handle loads it once managed with ease.

- Slower Operating Speeds: Decreased productivity due to sluggish performance.

- Higher Fuel Consumption: Increasing costs associated with inefficiency.

If these issues are impacting your productivity, it may be time for an upgrade.

Safety Concerns

As forklifts accumulate wear and tear, safety features can degrade, putting operators and your workplace at risk. Watch for warning signs such as:

- Worn brakes

- Sluggish steering

- Malfunctions in lifting mechanisms

Proactively replacing a forklift with safety concerns helps prevent potential accidents and ensures compliance with safety standards.

Difficulty Finding Replacement Parts

Over time, manufacturers may discontinue production of replacement parts for older forklift models. Limited parts availability can lead to delays in repairs and higher costs, making it increasingly difficult to maintain an aging forklift. Partnering with a reliable dealer can help you source parts, but persistent difficulties might signal the need for a newer model.

Outdated Technology

The forklift industry continually evolves, with newer models offering:

- Improved efficiency through advanced powertrains.

- Enhanced safety features, like collision prevention systems and operator monitoring.

- Greater operator comfort, reducing strain and increasing productivity.

If your forklift is lacking modern features, it could be holding back your operation compared to competitors utilizing updated technology.

Take Action Before Issues Escalate

By keeping an eye on these warning signs, you can proactively evaluate whether your forklift fleet is still serving your operational and financial goals. Replacing an aging forklift at the right time ensures optimal performance, cost savings, and safety for your team.

7. How to Extend Your Forklift’s Lifespan

Maximizing the return on investment (ROI) for your forklifts requires more than understanding their useful and economic life. The key is to adopt strategies that keep your equipment running efficiently, safely, and cost-effectively for as long as possible. Here are some practical steps to help extend your forklift’s lifespan:

Prioritize Preventative Maintenance

Regular maintenance is the foundation of a long-lasting forklift. Implement a preventative maintenance program that follows the manufacturer’s recommendations to address minor issues before they become costly repairs. Routine inspections, timely lubrication, and replacement of worn parts are essential for maintaining peak performance.

Train Operators Effectively

Skilled operators not only enhance safety but also reduce unnecessary wear and tear on your forklifts. Comprehensive training programs should cover proper operation techniques, load handling, and pre-shift inspections. Educating operators on smooth acceleration, careful braking, and appropriate lifting practices can prevent damage and prolong equipment life.

Use the Right Forklift for the Job

Choosing the right forklift for your specific tasks is critical. Overloading or underutilizing a forklift can lead to premature wear or inefficiencies. Work with a forklift specialist to ensure the model and capacity of your equipment match the demands of your operation, whether it’s heavy lifting, tight spaces, or long hours.

Monitor and Analyze Usage Data

Tracking operational data, such as hours of use, types of loads, and environmental conditions, provides valuable insights into your forklift fleet’s performance. Use this information to optimize scheduling, distribute workloads evenly, and identify inefficiencies. This proactive approach helps balance wear and tear across your equipment.

Explore Alternative Ownership Models

For some businesses, leasing or renting forklifts might be a smarter financial choice than purchasing. These models provide access to newer equipment with the latest features while avoiding the upfront costs of ownership. Ri-Go Lift Truck offers flexible financing options tailored to your operational needs, ensuring you have the best equipment without overextending your budget.

By combining these strategies, you can significantly extend the lifespan of your forklifts, enhance their performance, and maximize your ROI. A well-maintained and appropriately utilized forklift fleet keeps your material handling operations efficient and reliable.

8. Forklift Disposal Options

When it no longer makes sense to repair your forklift, you have several disposal options.

When your forklift reaches the end of its lifecycle, you have several options for responsible disposal. Here’s a breakdown to help you decide:

Trade-In:

Upgrade your fleet seamlessly by trading in your old forklift for a new model. You’ll receive a credit based on its condition, age, and model, making the transition smoother on your budget.

Sell Privately:

Maximize your return by selling directly to another business. Use online platforms and industry publications to reach potential buyers. However, be prepared for the time investment required for advertising and negotiations.

Auction it Off:

Consider an auction for a potentially higher sale price, especially for older models. Competitive bidding can drive up the value, but remember that auction fees and the final sale price can be unpredictable.

Professional Removal:

For convenience, consider a forklift removal service. They handle the entire process, including pickup and disposal, freeing up your time and resources. However, factor in the associated removal fees when making your decision.

Recycle It:

If your forklift is beyond repair, responsibly recycle its metal components. This eco-friendly approach generates income based on the weight of the scrap metal, though the return may vary depending on market fluctuations.

Need Guidance?

Ri-Go Lift’s experienced team can help you determine the best disposal method for your specific needs. Contact us today for a consultation.

9. The Linde Advantage: Why Linde Forklifts Last Longer

Linde forklifts last twice as long as other brands.

When investing in a forklift, longevity and productivity are key considerations—and that’s where Linde truly excels. Unlike other brands built to a 10,000-hour lifespan, Linde forklifts are engineered to last an impressive 20,000 hours, doubling their operational life and providing exceptional long-term value. This remarkable durability helps justify Linde’s premium price tag, offering unmatched performance and reliability over time.

Why Linde Lasts Longer

Linde forklifts are a testament to German engineering excellence, known for precision and quality. Key design features, like the hydrostatic drive system, eliminate traditional transmission components, reducing wear and tear and enhancing efficiency. Additionally, Linde’s engines operate at lower RPMs compared to competitors, minimizing engine wear and extending their lifespan significantly. These thoughtful innovations ensure that Linde forklifts are built not just to work but to last.

Unmatched Productivity

Durability is only part of the equation. According to TÜV Nord, an independent vehicle inspection and consulting firm, Linde forklifts are up to 22% more productive than any other manufacturer. This productivity boost means you’ll accomplish more in less time, maximizing efficiency and reducing operational costs.

With Linde, you’re not just investing in a forklift—you’re investing in a high-performance machine that delivers unmatched durability, efficiency, and long-term savings.

Need a New Forklift? Contact Ri-Go

If you are in the market for a new forklift, contact us. Our knowledgeable staff can help you choose the perfect one for your needs.

Since 1977, Ri-Go Lift Truck has been serving customers in Ontario and Quebec with everything they need for material handling. We are committed to providing you with quality service and a high level of customer satisfaction.

We are your authorized dealer for the following top brands:

- Linde Lift Trucks, Power Pallet Trucks, Tow Tractors and Stackers

- Hangcha Forklifts Full Lineup of Electric & IC Equipment

- Blue Giant Lift Trucks and Pallet Movers

- Komatsu Forklifts and Reach Trucks

- Mariotti Lift Trucks – The Worlds Smallest Lift Truck

- Baoli Lift Trucks

- Advance Sweepers and Scrubbers

- Skyjack Genie Booms and Scissor Lifts

In addition to our authorized distributorships, we can also provide you with:

- Large selection of used forklifts

- Operator Training Department – open 7 days a week

- Parts Departments – over 1.4 million dollars of parts on hand for all makes and models

- Service Department – highly trained technicians

- Leasing and Rentals

No matter what your material handling needs are, we can help. Contact us today to let us know how we can be of service.

What Our Customers Think…

“I’ve been using RIGO Lift for the last 3-4 years now for my equipment rental needs. They have a fantastic crew working together and they are VERY efficient and reliable as a whole. Whenever I need electric equipment which is hard to come by, I know they are always able to provide. Their equipment is rare to breakdown because they provide machinery that is well kept and in good condition. I definitely recommend you reach out to Steve and the team because you will not be disappointed!” – Heloise Vieira